Our Dead Center Points Services

* Hard alloy dead center dressing

* PCD dead center customization

* Hard alloy modified to PCD dead center

* PCD dead center regrinding

Alias: Diamond dead center

For high precision shaft rotary products, such as

PCD (Poly Crystalline Diamond) is, next to a solid diamond, the hardest material known to man. As the market demand increases,For high precision shaft products,Materials such as hard alloy, alloy steel, wear-resisting cast iron, ceramics, etc.The machining process must use a center.

We supply machine centre points equipped with PCD sintered in five veins into a tungsten carbide carrier. Benefits:

* Ultra-High Wear Resistance And Service Life Of 80-180 Times That Of Hard Alloy Center.

* Good Thermal Conductivity, Reduce The Friction Heat Generated In The Work And Avoid The Central Hole Of The Workpiece Being Burned And Deformed, Causing Changes In The Central Position And Affecting The Machining Accuracy.

* The Friction Coefficient Is Much Lower Which Cangreatly Reduce The Friction Resistance, And The Vibration Of Workpiece, To Improve The Processing Accuracy.

* Polycrystalline Diamond Under 650° Showed Good Chemical Inertness, Resistant To Strong Acid,Alkali,Suitablefor All Kinds Of Operating Mode Under The Condition Of Work.

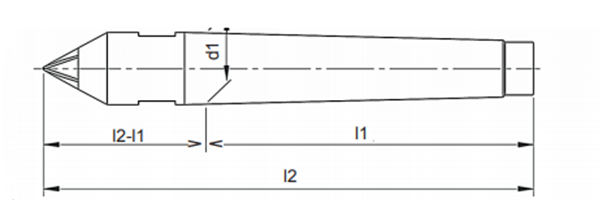

The specification of PCD dead center

|

Type |

D2 |

D4 |

H1 |

L3 |

thread |

L1 |

L2 |

L2-l1 |

|

Full Center |

12.2 |

7 |

|

|

|

53.5 |

80 |

26.5 |

|

|

18 |

7 |

|

|

|

64 |

100 |

36 |

|

|

24.1 |

11 |

|

|

|

81 |

125 |

44 |

|

|

34.6 |

14 |

|

|

|

102.5 |

160 |

57.5 |

|

|

44.7 |

15.8 |

|

|

|

129.5 |

200 |

70.5 |

|

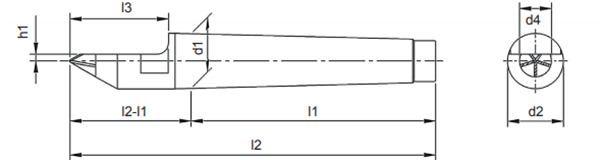

Type |

D2 |

D4 |

H1 |

L3 |

thread |

L1 |

L2 |

L2-l1 |

|

Half Center |

12.2 |

7 |

1.5 |

22 |

|

53.5 |

80 |

26.5 |

|

|

18 |

7 |

2 |

30 |

|

64 |

100 |

36 |

|

|

24.1 |

11 |

3 |

38 |

|

81 |

125 |

44 |

|

|

34.6 |

14 |

5 |

50 |

|

102.5 |

160 |

57.5 |

|

|

44.7 |

15.8 |

7 |

63 |

|

129.5 |

200 |

70.5 |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Through this research tour, Moresuperhard team learnt more about MLED industry (applications&markets) and know the differences among LCD, OLED, MINI-LED, MICRO-LED...MLED is seen as the next generation or even the ultimate display solution, with applications in large business displays, wearables, in-car screens, cinema screens and AR glasses. MORESUPERHARD will follow the trend according to the needs of market development and research and development to match the grinding and polishing solutions for MLED industry. In the following articles we will introduce more information about the MLED industry.

Diamond dresser is a commonly used tool for dressing grinding wheels.Diamond dressing pen is used to dress the grinding wheel in the way of turning. This dressing method is simple and convenient to operate, and the cost is low.The efficiency of the dressing wheel of the diamond dressing pen will directly affect the production efficiency, so it is very important to use the diamond dressing pen scientifically.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088