Products

Home / Products / Brazing / PCD Brazing Machine > Brazing Alloy

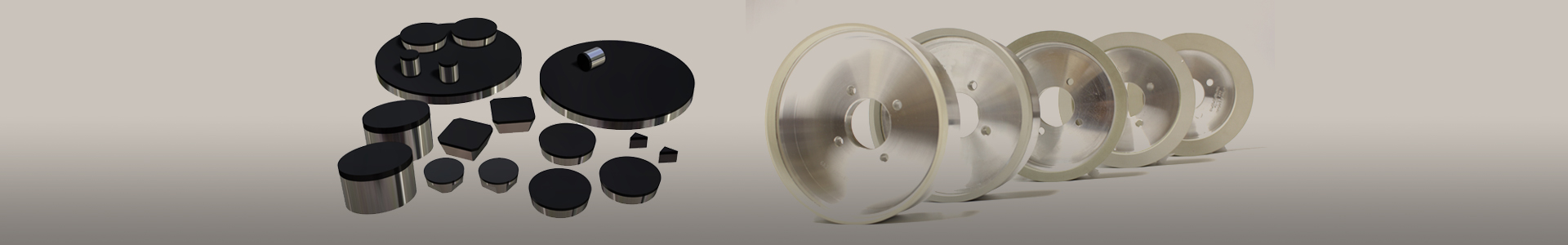

There are special technical requirements for the welding of polycrystalline diamond composite (PDC) and polycrystalline cubic diamond boron nitride. After years of research, we have designed a series of special solder suitable for PDC and PCBN welding. In the manufacturing process of solder, all high-quality raw materials are used for production, and the leftover materials are completely removed in the processing process to ensure the stability of quality and reliable performance of products.

Application:

We have developed MAG 611-618 series of silver filler metals according to the working conditions of different industries, which are respectively suitable for brazing the workpiece under the conditions of normal temperature, medium temperature and high temperature or under the conditions of constant, alternating, vibration and impact load.

Sandwich composite filler metal is specially used for brazing large area workpieces, which has significant buffering effect on impact and vibration load.

Applicable technology

Induction welding (automatic induction welding), flame welding, furnace welding, resistance welding and other brazing processes, welding needs to be used together with the brazing flux.

Specifications:

Filament series: coiled wire with a diameter of 0.25mm or more, straight bar with a diameter of 1.5mm or more.

Band series: band or flat wire with a thickness of 0.10mm or more and a width of 2.2mm to 60mm

Sheet series: square sheet, rectangular sheet, round sheet, etc. and other preformed sheets with special requirements;

|

Grade |

Composition |

Fusing Temperature

(℃) |

Strength of Extension

(MPa) |

Characteristics |

|

MAg611 |

AgCuZnCdNi |

620-630 |

410 |

Good fluidity, good plasticity, high welding strength |

|

MAg612 |

AgCuZnCdNiCo |

635-690 |

440 |

Good seam filling, strong fatigue resistance and high comprehensive performance |

|

MAg613 |

CuZnNiCoMn |

670-790 |

460 |

Brazing joints have strong impact resistance and are suitable for brazing in furnace |

|

MAg614 |

AgCuZnNiCo |

660-708 |

450 |

High strength, good wettability, strong impact resistance, suitable for heavy load tool fiber welding |

|

MAg615 |

AgCuZnNico |

690-720 |

460 |

High strength at high temperature, strong impact resistance, mainly used for induction fiber welding |

|

MAg616 |

AgCuZnNiMn |

678-695 |

470 |

High strength, good wettability, strong impact resistance, suitable for brazing mining tools |

|

MAg617 |

AgCuZnNiMn |

650-695 |

450 |

High strength, good wettability, strong impact resistance, suitable for fiber welding of mining tools |

|

MAg618 |

AgCuZnNiMn |

670-720 |

460 |

High strength, good wettability, strong impact resistance, suitable for fiber welding of mining tools |

|

S303 |

Ag45CuZn |

665-745 |

390 |

Good fluidity, good plasticity, smooth and clean surface of bit joint |

|

S304 |

A50CuZn |

690-775 |

380 |

Good fluidity, good plasticity, smooth and clean surface of bit joint |

|

S305 |

Ag40CuZnCdNi |

595-605 |

390 |

Lowest melting point, excellent comprehensive performance |

|

S306 |

Ag50CuZnNi |

645-675 |

435 |

High strength, white surface of drill joint |

|

MT851 |

AgCuZncdNi |

640-690 |

Sandwich |

Good impact resistance, effectively prevent the cracking of cemented carbide after welding, suitable for flame brazing |

|

MT861 |

AgCuZnNiMn |

640-695 |

Sandwich |

Suitable for induction brazing |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

We continously improve and optimize diamond formulations to adjust the performance of size,shape,strength wear resistanc...

Diamond is the hardest substance among known minerals, and the amount of wear when matched with various metal and non-me...

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 13323855288