Characteristics and application of precision and ultra-precision grinding

Precision grinding refers to the selection of fine grain grinding wheel on the precision grinding machine and the fine dressing of the grinding wheel to make the grinding grain have Micro toughness and contour. After grinding, The grinding marks left by the grinding surface are extremely fine and the residual height is extremely small. With the help of the non-spark grinding stage, a surface grinding method with machining accuracy of 1~0.1 muon and surface roughness Ra of 0.2~0.025 muon can be obtained.

Ultra-precision grinding is a sub-micron processing method with the processing accuracy below 0.1 microns and surface roughness lower than 0.025 microns. In recent years, the development of ultra-precision grinding is very fast. There are some grinding processes related to ultra-precision grinding, such as mirror grinding, micro-grinding and high-speed grinding.

1.Features of precision and ultra-precision grinding

(1)precision and ultra-precision grinding is a system engineering

Precision and ultra-precision grinding is not a simple processing method, it has become a system engineering, it includes processed materials, precision and ultra-precision grinding mechanism, precision and ultra-precision grinding machine, grinding wheel and its dressing, workpiece positioning and clamping, detection and error compensation, working environment and human skills. Precision and ultra-precision grinder are the key to ensure the machining accuracy.

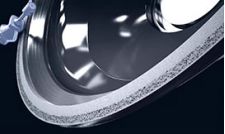

(2)the super-hard abrasive wheel is the main tool for precision and ultra-precision grinding

Superhard grinding is a very thin layer of cutting, grinding depth is very small, the requirements of abrasive materials with high temperature strength and high temperature pressure, so the use of diamond and cubic boron nitride superhard abrasive; Because of the low requirement of surface roughness, super-hard abrasive micro-powder grinding wheel is mostly used for grinding.

(3) precision and ultra-precision grinding is an ultramicro cutting process

Precision and ultra-precision grinding is an extremely thin cutting that is done inside a crystal with a very small removal allowance and is likely to be equivalent to the degree of precision required by the workpiece.

2.Application of precision and ultra-precision grinding

(1)Grinding steel and its alloys and other metal materials, especially hardened steel after quenching and other treatment.

(2)Grinding non-metallic hard and brittle materials, such as ceramics, glass, quartz, semiconductor materials, stone, etc.

(3)At present, there are mainly external grinding machine, surface grinding machine, internal grinding machine, coordinate grinding machine and other ultra-precision grinding machine, used for ultra-precision grinding of the outer circle, plane, hole and hole system.

(4)Precision and ultra-precision grinding and its free abrasive processing are complementary.

<< Prev Article:PCD tools for Graphite precision turning

<< Next Article:Why PCD tools are not suitable for rough processing?

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220