During the grinding process of CNC grinder, customers will encounter various grinding problems

1. The grinding wheel is seriously clogged and cannot grind the workpiece, resulting in reduced efficiency, increased load, and the possibility of excessive temperature, smoke, or even breakage of the workpiece.

2. The working time is tight, the sharpening is not done in time or the sharpening is forgotten, resulting in serious blockage.

3. The grinding wheel wears too quickly.

4. The grinding wheel particle size or formula is inappropriate, resulting in poor grinding conditions, etc.

Specifications of cnc diamond grinding wheel:1A1 D100*H20*T20*X6 D170

Type of binder:Resin bond,metal bond and hybrid bond

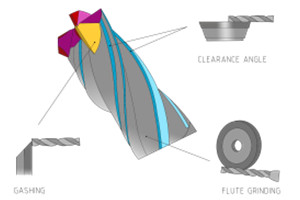

Applications:① Groove ② Clearance between cutter body and drill bit ③ Circumferential cutting edge angle ④ Drilling and milling tool cutting groove ⑤ Step ⑥ External circle ⑦ Drill tip

Processing materials:tungsten carbide,cermet,ceramic

Processing rotary tools like reamers,end mills,drills

Resin bond metal bond hybrid bond

CNC grinding cases from our customer

Grinding wheel model: 1A1 D100*H20*T20*X6

Particle size: D170

Workpiece and workpiece material: tungsten carbide drill bit

Processing part: Drill bit grooving

Drill bit diameter: 27mm

Number of processing edges: 14

Processing type: Wet grinding (synthetic oil)

Speed: RPM3480 Feed: 60 per minute

Grinder: Walter CNC

Using Mresuperhard 1A1 hybrid bond diamond grinding wheel helps customers improve grinding efficiency and reduce the frequency of dressing.

Moresuperhard cnc grinding wheel features

1. Suitable for high-efficiency grinding processing with rapid feed.

2. Good wear resistance and shape retention.

3. It has good self-sharpening properties, generates less heat during grinding, reduces burns on the workpiece, and meets the high-precision requirements of the tool.

4. No clogging, easy to trim, extend the trimming cycle and reduce processing costs.

5. The cutting edge quality of the grinding workpiece is consistent and the smoothness is high, which ensures stable quality when processing downstream products.

Dressing solutions for cnc grinding wheel

1. Dressing of general grinding wheel

Recommended grinding wheel parameters: silicon carbide (green) or aluminum oxide (white or pink);

particle size: 80-120 mesh, also depends on the grinding wheel particle size; hardness E, G, H, J/K.

Trimming parameters

Grinding wheel linear speed: 2-6m/s; dressing wheel linear speed: 8-25m/s; swing speed: 200-1000mm/min; rough trimming: 0.02-0.08mm/time; fine trimming: 0.005-0.02mm/time.

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088