Classification and application of precision ceramics

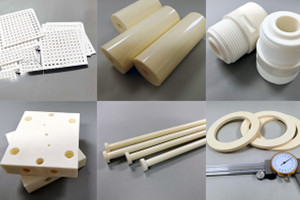

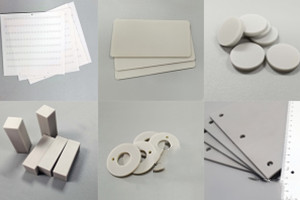

Precision ceramics are high-precision ceramics manufactured using "strictly selected or synthesized raw material powders" through "strictly controlled manufacturing processes" and "precisely adjusted chemical compositions".

Precision ceramic materials can make products lighter, more efficient, more durable, reduce maintenance intervals and lower operating costs. Due to their significant high-temperature capabilities, hardness, and electrical properties, they are often used to replace metals, polymers, and refractory materials in a variety of applications.

Common precision ceramic materials

Alumina ceramic (Al 2 O 3 )

Alumina ceramic is one of the most commonly used precision ceramic materials. Alumina ceramics are used in many applications such as containing molten metal where the material operates at very high temperatures under heavy loads, as an insulator in spark plugs, and in some unique applications such as dental and medical uses. Chromium-doped aluminum oxide is used to make lasers.

Aluminum nitride ceramic (AlN)

Aluminum nitride ceramics are used as precision ceramic materials in many electronic applications, such as circuits operating at high frequencies. It is also suitable for integrated circuits.

Zirconia ceramic (ZrO 2 )

Zirconia ceramic is a very strong precision ceramic material with a Vickers hardness of up to 1250. Zirconia ceramics are often used to make ceramic blades and ceramic parts

Silicon carbide ceramic (SiC)

Silicon carbide ceramics are considered one of the best precision ceramic materials for extremely high temperature applications

Hexagonal boron nitride ceramic (HBN)

Hexagonal boron nitride ceramics have a wide range of uses and have excellent mechanical properties, high temperature resistance, thermal shock resistance, ablation resistance, and molten metal corrosion resistance, making them widely used in aerospace, electronics, metallurgy, machinery, nuclear energy, etc. fields with potentially important application value.

Silicon nitride ceramic (Si 3 N 4 )

Silicon nitride (Si 3 N 4 ) has the most versatile combination of mechanical, thermal and electrical properties of all precision ceramic materials. It is a high-performance precision ceramic that is very hard and has excellent resistance to thermal shock and impact. It exceeds the high temperature capabilities of most metals and has excellent creep and oxidation resistance. Additionally, its low thermal conductivity and high wear resistance make it an excellent material capable of withstanding the harshest conditions in the most demanding industrial applications. Silicon nitride ceramics are an excellent choice when high temperatures and high load capabilities are required.

Machinable Ceramics (Macor)

Macor processable crystallized glass ceramics offer the versatility of high-performance polymers, the processability of metals, and the performance of advanced precision ceramics.Macor is an excellent electrical and thermal insulator that performs well in high temperatures, vacuums and corrosive environments.

This article gives you a brief understanding of the types and applications of precision ceramics. Due to the high hardness and brittleness of ceramic materials, most of the processed ceramic components will produce various types of surface or sub-surface damage. So how to grind ceramic materials? Let’s take a look at the next article.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088