Diamond Polishing Paste & Diamond Compound

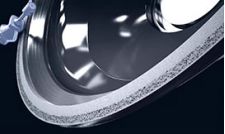

Diamond polishing paste is is one of soft abrasive tools, made of precision -graded diamond powder (diamond and CBN) and other fine materiality. The diamond powder has high bulk purity, high surface purity and high impact strength crystals. Diamond compounds are used for polishing hard and brittle materials to give fast stock removal and superior surface finish.

Abrasive Grain Sizes

W0.25 W0.5 W1 W1.5 W2.5 W3.5 W5 W7 W10 W14 W20 W28 W40 W60

Available Packaging

Syringes : 5, 10, 18, 20, 25 gram

Jars: 5, 10, 18, 20, 25, 100, 250, 500, 1000 grams

Available Concentrations

• Medium

• Standard

• Heavy

Diamond Compound is soluble in both oil and water

* Oil Diamond Polishing Paste

Good wettability ,strong grinding force , suitable for processing of hard materials such as tungsten carbide, hardened steels and ceramics, dies, molds, ceramics and sapphire windows,measuring devices, grinding tools and seals

* Water Diamond Polishing Paste

Low viscosity,high processing efficiency, slightly corrosive to metal,workable in hostile grinding environment,suitable for processing hard and crisp material such as glass,ceramics and gemstone .

diamond polishing pastes is used for polishing and cleaning metals, carbide, glass, ceramics, dies & molds, gem, mineral surfaces, semiconductors , optical instruments and other hard materials. Also suitable for polishing metallographic and petrographic samples

Abrasive Characteristics in diamond Compounds

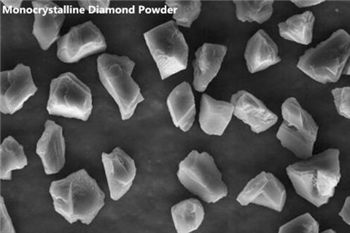

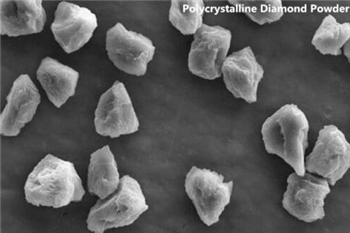

Available in monocrystalline or polycrystalline diamond for fastest stock removal and finest surface finish with reduced sub surface damage

* The cutting rate is even further enhanced when selecting polycrystalline diamond rather than monocrystalline. Polycrystalline diamond particles consist of angular, blocky shaped grains providing numerous cutting facets, resulting in less deformation and a superior surface finish.

* Monocrystalline diamond particles consist of single grains that have sharp edges which ensure clean and efficient cutting action providing high material removal rates.

How to use diamond polishing paste

1. Most grinding, lapping and polishing using diamond paste is done progressively; starting with a coarser grade and then finishing with a finer grade.

2. Make sure the sample or work piece is thoroughly cleaned/rinsed before you use a finer grade diamond paste. Apply the diamond paste on a billiard type cloth and spread evenly; a lubricant or extender (mixture of glycol / alcohol / water / detergent) can be used to thin the paste.

3. 25 - 90 micron for rapid stock removal.

6 - 14 micron for lapping and pre-polishing.

0.25 - 3 micron for final polishing

<< Prev Article:Quality Control For Resin Diamond Wheel for Cylindrical Grinding

<< Next Article:Selection of grinding wheel

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220