Selection of grinding wheel

2019-11-01 16:06:23

Abrasive, hardness, particle size and bond are the main factors affecting the performance of grinding wheel.

grinding steel and other toughness materials should choose corundum type abrasive;Silicon carbide abrasive should be selected for grinding brittle materials such as cast iron and hard alloy;Hard alloy, ceramics, semiconductor and other high hardness brittle difficult to process materials generally choose diamond grinding wheel. For steel rollers of different materials, corundum shaped sand wheel is generally selected to obtain higher grinding accuracy to meet the surface quality requirements.

2. Particle size

Particle size refers to the size of abrasive particles. The grinding wheel with large particle size has the advantages of not being blocked easily, high durability and strong cutting ability, while the grinding wheel with small particle size has the advantages of stable performance and high surface quality. For the general CNC roll grinding machine, choose the size of 24~60 grinding wheel can achieve grinding accuracy. For rollers with high precision requirements, 150 particle size grinding wheel can be used for precision grinding. The grit of grinding wheel is W64-W14 can be selected for ultrafine grinding or mirror grinding.

3. Hardness

Hardness refers to the degree of hardness of grinding wheel when the grinding grain falls off under the action of external force. The choice of hardness mainly depends on the workpiece material, grinding efficiency and surface quality. In roller grinding, the grinding wheel wears too fast, which indicates that the grinding wheel is too soft for grinding.If the grinding wheel has too much grinding force, the sand is not easy to fall off, or the grinding wheel has too much power, the grinding surface will be burned, which indicates that the selected grinding wheel is too hard and the grinding wheel needs to be replaced.

4. Bond

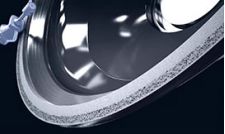

The function of the binder is to bond the abrasive particles together so that the grinding wheel is formed and has a certain hardness. The most commonly used grinding wheel binders are vitrified bond (V) and resin bond (B). Vitrified bond grinding wheel is suitable for grinding ordinary carbon steel, alloy steel, stainless steel, cast iron, hard alloy, non-ferrous metals, etc. While resin bond grinding wheel is widely used for rough grinding, rough grinding, cutting off and free grinding. In terms of performance, roll grinder generally choose ceramic grinding wheel.

<< Prev Article:Diamond Polishing Paste & Diamond Compound

<< Next Article:Best grinding wheel or “YOUR”wheel

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220