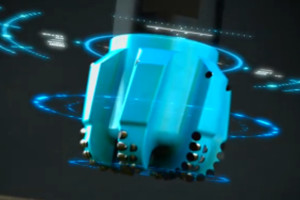

What is PDC drill bits?

PDC bit is the abbreviation of polycrystalline diamond compact bit, also known as polycrystalline diamond cutting block bit or composite bit. Since the introduction of PDC cutting blocks by the General Electric Company of the United States in 1973 and the development of the first PDC bit, the PDC bit has been widely used in oil drilling due to its advantages of fast drilling speed, long life and high footage. Almost all drill manufacturers have adopted this technology and started producing their own line of PDC drill bits.

Structural characteristics of PDC drill bits

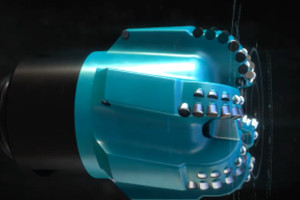

PDC drill bits are composed of drill body, PDC cutting teeth and nozzles.PDC drill bits are divided into two series of steel body and matrix according to the structure and manufacturing process.

Steel body PDC drill bit

The entire bit body of the steel body PDC bit is made of medium carbon steel and machined to shape. Drill holes on the working surface of the drill bit, and fasten the PDC cutting teeth to the crown of the drill bit by means of a press-fit tight fit. The crown of the drill bit is treated with surface hardening process (spraying tungsten carbide wear-resistant layer, carburizing, etc.) to enhance its erosion resistance. The main advantage of this kind of drill is that the manufacturing process is simple; the disadvantage is that the drill body is not resistant to erosion, and the cutting teeth are difficult to fix, so it is rarely used at present.

Matrix PDC dril bits

The upper part of the matrix PDC bit body is a steel body, and the lower part is a tungsten carbide wear-resistant alloy matrix, which is manufactured by powder metallurgy sintering process. Use low-temperature solder to weld the PDC cutting teeth on the reserved groove of the carcass. The tungsten carbide matrix has high hardness and erosion resistance, so the matrix PDC bit has a long service life and high footage, and is currently widely used.

How PDC drill bit work ?

The PDC bit breaks the rock by cutting. The self-sharpening cutting teeth can easily cut into the formation under the action of drilling pressure, and move forward to shear rock under the action of torque. Multiple PDC cutting teeth work at the same time, there are many free surfaces of the rock at the bottom of the well, and the rock is easily broken under the action of shearing, so the rock breaking efficiency is high and the drilling speed is fast.

How to use PDC drill bit correctly ?

PDC bits work best in large homogeneous soft to medium hard formations. It is not suitable for drilling gravel layers and soft-hard formations.

1.Drilling with low drilling pressure, high speed, and large displacement, the drill bit has a good effect.

2.Before the drill bit goes into the well, the bottom of the well should be cleaned to ensure that there is no metal falling.

3.When the drill bit is just going down the well, it is necessary to run with a small drilling pressure and a low speed, and resume normal drilling after the bottom of the well is formed.

4.The PDC drill bit is an integral drill bit without any moving parts, suitable for high-speed turbo drilling.

Moresuperhard company provide PDC composite sheet and diamond grinding wheel for your oil driling bits

PDC compsite sheet for pdc drill bits

Dimaond grinding wheel for grinding and PDC drill bit

Vitrified diamond grinding wheel for pdc drill bit

Resin bond diamond grinding wheel for grinding pdc drill bits

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088