The importances of sharpening and regrinding PCD tools

More and more companies that process MDF, particleboard and other panels used in furniture production are sourcing and using PCD tools. Diamond milling cutters, saws and drills allow you to obtain high quality products with a minimum of rejects. However, diamond tools require regular sharpening. If expensive dimaond tools are to be used for a long time, they must be resharpened in time.

The advantages of regrinding PCD tools

Increased tool life;

Improve labor productivity;

Solved the problem of high-quality processing of wood-based panels;

Helps reduce products cost

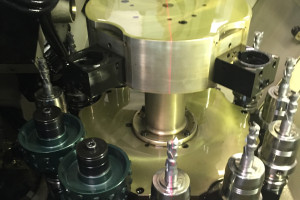

MT 198 NC pcd grinding machine is equipped with automatic controls. This helps to achieve the desired cut surface quality in the end and maximizes possible regrinding times in the future.

- MT-198NC spindle can be raised and lowered, B axis braking system and MPG handwhell provides added convenience in machine running test when production of special tools.

- 198NC PCD PCBN Tool Grinder, is a versatile machine, perfectly suited for manufacture and resharpen high-quality tools.

- The high-end machine, MT-198 has creative technologies to make it convenience to machine a wide range of special tools such as, spindle can be vertical movement, B axis braking system and MPG handwheel for easy setting and running test.

Sharpening of diamond circular saws and marking discs;

Regrinding of various tips and attachment tools;

Sharpening of crushers and milling cutters for edge banding machines;

Sharpening of diamond filled drill bits.

The use of automatic equipment guarantees edge restoration with minimal loss of material, resulting in a longer service life. The sharpening of diamond saws and milling cutters is carried out by experienced experts trained by sharpening equipment manufacturers.We guarantee full restoration of PCD tool performance balance and control of cutting edge geometry and quality.

If the diamond cutting tool is damaged, we will repair the tool by welding a new PCD cutting insert. If your diamond Tools can not be sharpened or repaired, we offer new diamond tools including pcd/pcbn tools and mcd tools.

Moresuperhard is a professional PCD diamond tools grinding and regrinding solutions supplier.Moresuperhard provide all products line of process diamond tools including pcd blanks,mcd diamond plate,laser cutting machine,carbide substrate,brazing machine(high frequency brazing machine and vacuum brazing machine),diamond grinding wheel,pcd grinding machine,dressing tools.

If you have any problems about grinding and regrinding pcd tools and diamond tools ,please contact us freely.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088