Manufacturing Process of Single Crystal Diamond Tools

The manufacturing process of single crystal diamond tools generally includes material selection, orientation, sawing, blanking, clamping, rough grinding, fine grinding and inspection. After the selected rough diamond is oriented and sawed along the maximum plane, the blanks of two cutters can be obtained, which can not only improve the utilization rate of diamond materials, but also reduce the total amount of grinding. The shape of the tool can meet the requirements of clamping (inserting or brazing) by blanking. Grinding is used for billet opening, rough and fine grinding.

The grinding of diamond is very different from the processing of other tool materials. The grinding mechanism has not been convincingly explained so far, and there are many factors affecting the grinding quality. Some technical issues of diamond tool grinding are discussed below.

Five major influencing factors encountered in diamond tool grinding

1. Influencing factors of grinding amount

It is found through experiments that the relationship between the amount of grinding and the grinding conditions is V=kv where V grinding volume k grinding rate v grinding speed p grinding pressure In addition, the grinding direction of diamond, the particle size of abrasive, and the distance of abrasive grains in cast iron pores Factors such as the setting condition will also change the size of the grinding rate, thereby affecting the amount of grinding.

2. Influencing factors of grinding quality

Diamond has high hardness and high brittleness. Although the surface roughness of the tool is easier to ensure during grinding, the blade is prone to chipping and the serration of the blade is not easy to reduce. Ultra-precision machining requires the cutting edge to be observed under a 500X microscope without chipping, so it is necessary to optimize the grinding process from all aspects to obtain a straight and perfect cutting edge.

If you are grinding diamond tools with cast iron discs then the particle size of the grinding powder and the condition of the grinding disc have an important influence on the grinding quality.

Due to the limitation of machining accuracy, the newly manufactured grinding disc has a relatively large unevenness on the disc surface, which has a certain impact on the stability of grinding.Therefore, for key processes such as sharpening or fine grinding of diamond tools, it must be carried out on a stable grinding disc surface.Since the abrasive grains will be continuously broken or lost during the grinding process, if it is not replenished in time, the diamond will directly contact the cast iron due to insufficient abrasive grain density on the disk surface, which will not only affect the grinding quality of the tool, but also cause the diamond to be squeezed and scraped. The effect destroys or blocks the pores on the disc surface, thereby reducing the service life of the grinding disc. Therefore, it is necessary to frequently add new grinding paste to the disk surface during the grinding process.

In addition, the pretreatment of the surface of the grinding disc before powder coating is also very important. Generally, it is necessary to use oil stone or coarser SiC grinding powder to grind the surface of the disc to remove the turning grooves and improve the flatness of the disc surface.

3. Influence of sharpening angle on grinding quality

The sharpening angle q is the angle between the direction of the grinding line speed and the blade. When q>0°, the grinding direction is from the blade body to the blade, which is called forward grinding; when q<0°, the grinding direction is from the blade to the blade body, which is called reverse grinding. Due to the high tensile strength of diamond, when grinding forward, the blade bears tensile stress, so the sawtooth degree after grinding is small; when grinding backward, the blade bears compressive stress, so the sawtooth degree after grinding is relatively large. When q is greater than and close to 0°, the blade can obtain the minimum sawtooth degree. At this time, the stress direction at the edge is basically parallel to the blade, and the blade has the highest tensile stress intensity in this direction. Another advantage of grinding parallel to the blade is that the grinding marks on the blade surface are also parallel to the blade, which will not be reflected on the machined surface during cutting, which helps to improve the quality of cutting.

4.The Influence of Disc Surface End Jump and Machine Tool Vibration on Grinding Quality

The end jump of the grinding disc surface and the vibration of the machine tool will cause the impact of the disc on the blade during grinding, thereby destroying the straightness of the blade, especially the impact of the end jump on the disc surface is more direct, because the impact direction caused by the end jump perpendicular to the disk surface. There is a critical value for the influence of disk end jump and machine tool vibration on the blade serration. When it is less than the critical value, the blade serration tends to zero; and when it is greater than the critical value, the blade serration increases sharply.

5.Influence of Deviation Angle on Grinding Quality

The deflection angle W is the angle between the actual grinding direction and the best grinding direction on the diamond surface to be ground. For the (110) surface, when grinding in the best grinding direction (w=0°), the diamond surface is very smooth, and the surface has large fluctuations, because in the best grinding direction, the roughness of the grinding disc surface is fully reflected; when w=45°, the diamond surface is still quite smooth, but the degree of undulation becomes smaller, and small grooves appear; when w=60°, dense deep grooves are produced on the diamond surface, and the grinding rate becomes very low; in the most difficult grinding direction, the diamond surface is full of pits, and the grinding rate is basically zero. The area of w<45° can be considered as a good grinding direction, and a smooth surface can be obtained. For (100) surface, its good grinding area is w<15°. The sawtooth degree tends to zero in the good sharpening area, and when w>45°, large chipping rapidly appears on the blade. Similar results can also be obtained for the (100) plane.

Do you think it is inconvenient to grind diamond tools with cast iron discs?

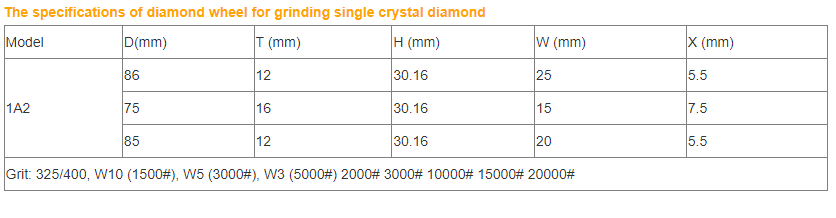

Moresuperhard company developed and produced metal bonded diamond grinding wheel and disc for rough and fine grinding single crystal diamond tools.Metal diamond grinding wheel is easy to use and high grinding efficiency.Moresuperhard metal bond diamond grinding wheel suit Coborn PG serises single crystal diamond tools grinding machine.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088