Relationships of rough grinding and fine grinding

Which step do you think is more important in a grinding process, rough grinding or fine grinding? “Fine grinding” is most selected from our customers. As the final step, they believe fine grinding is protagonist in their job. One of my customers told me a sentence before, “Fine grinding is fine, everything is fine.” However, I do not agree with his thought.

Fine grinding is important, but we cannot ignore the effect of rough grinding. It is the beginning of one project, if we do not control the quality well in first step, it is impossible to make second and every follow step well.

For example, in PCD or PCBN tools grinding. We often meet the issue of large chipping edge in fine grinding process. Generally, the first thing came to mind is changing fine grinding wheel, choose finer grit size, or change current grinding wheel supplier.We tend to ignore the issue in last step. If we get a 0.05mm chipping in rough grinding, how could we reach 0.005mm in next step? Guarantee the chipping edge under 0.02-0.03mm in rough grinding, then we can get 0.005mm cutting edge easily.

When we do a wonderful job in rough grinding, we can get 8 times efficiency improvement in maximum. It decreases lots of time in fine grinding, no need to take much time to remove the big scratches which generates in rough grinding. In conclusion, we say the first step is always hardest, the first step is always important. Rough grinding as the first step in production process, we should complete it well and stable, or we will never get good quality in fine grinding.

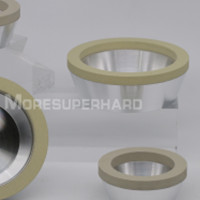

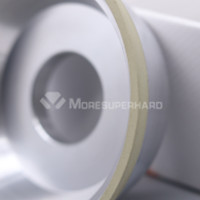

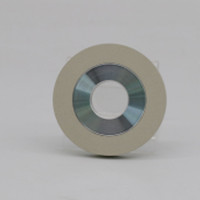

Moresuperhard as a professional ultra-hard tools grinding solutions supplier.Whether you have coarse or fine grinding problems, we can help you solve them.Rich experience in grinding PCD/PCBN/CVD/HPHT tools.And moresuperhard diamond grinding wheel suit all popular grinding machine like coborn,agathon,ewag,waida,wendt and others.

400#-10000# vitrified diamond grinding all can be supplied.

More grinding knowledge,please contact us freely.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088