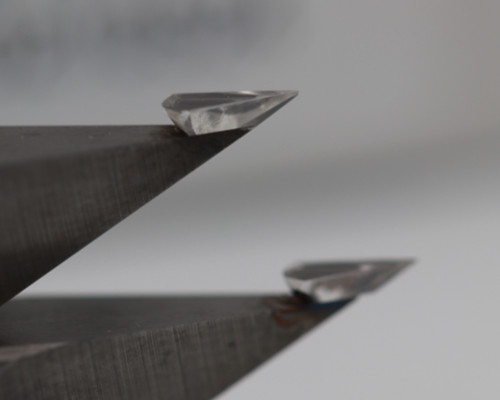

Single crystal diamond tool is a high-performance cutting tool made of single crystal diamond. It is widely used in precision machining of metals, non-metals and composite materials due to its excellent hardness, wear resistance and thermal conductivity. Its ultra-high cutting performance enables single crystal diamond tool to achieve high-efficiency and high-precision machining, and is particularly suitable for aerospace, automobile manufacturing, electronic component processing and high-end mold manufacturing. This kind of tool not only improves the machining quality, but also extends the service life of the tool and reduces production costs.

The main difficulty in grinding single-crystal diamond tools lies in their extremely high hardness and brittleness, which makes it easy to produce chipping and cracks during the grinding process. At the same time, the high temperature generated during the grinding process may affect the performance of the tool and needs to be effectively controlled. In addition, in order to meet the requirements of high-precision applications, the surface quality and shape accuracy must be strictly controlled, and the processing of complex geometric shapes also increases the challenge of the process, which overall improves the requirements of grinding technology.

1.Diamond grinding wheel mechanical grinding single crystal diamond tools

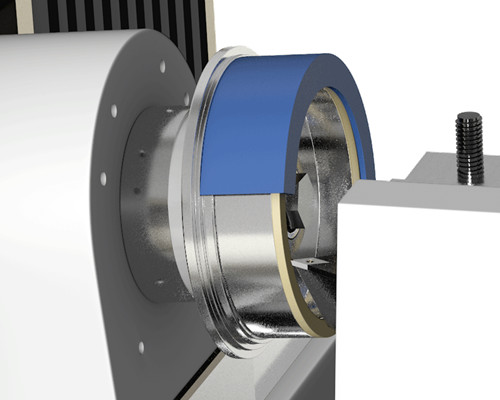

Grinding single crystal diamond tools with diamond grinding wheels is the most common method and can provide good grinding efficiency. The grit and bond type of the grinding wheel can be selected according to specific needs. Currently, both metal bond diamond grinding wheels and vitrified bond diamond grinding wheels are widely used for grinding single crystal diamond tools. Moresuperhard provides high-quality diamond grinding wheels for grinding single crystal diamond tools. Grinding wheels of different grits and models can be adapted to various grinders from rough grinding to fine grinding.

2.Laser grinding single crystal diamond tools

Laser grinding can achieve the processing of complex-shaped single-crystal diamond tools, but the equipment cost is high, 40%-50% higher than that of mechanical grinding equipment. Laser cannot directly process finished tools, and diamond grinding wheels or cast iron discs are still needed for super-precision grinding.

3.Mechanical grinding of single crystal diamond tools with cast iron discs/steel disc

Diamond abrasive paste is applied to the surface of the cast iron disc, and the hardness and rigidity of the cast iron disc are used to bring the diamond particles into contact with the surface of the workpiece. The diamond particles in the abrasive paste are cut by friction with the single crystal diamond tool to remove trace materials on the surface, thereby achieving a grinding effect. Cast iron disc and steel disc are suitable for ultra-fine grinding single crystal diamond tools.Because cast iron disc grinding can only be done with manual equipment, it places high demands on the grinders and requires experienced masters.

Moresuperhard recommends you to use diamond grinding wheel to grind single crystal diamond tools. If you use high rigidity PCD tool grinder, you may not need to change the equipment, just replace the grinding wheel with different formula to produce single crystal diamond tools directly. Moresuperhard provides single crystal diamond tool grinding solutions and consumables required for the production process of single crystal diamond tools, such as single crystal diamond sheets, vacuum welding machines, diamond grinding wheels, single crystal tool grinders and grinding wheel dressing tools.

A technical guide to selecting diamond grinding wheels for PDC cutter . Learn how ceramic and resin bond diamond wheels improve efficiency, precision, and tool life in oil & gas and mining applications.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088