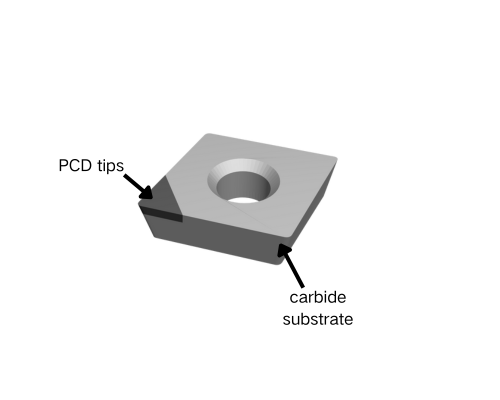

Components of PCD Cutting Tools

PCD tools are made of polycrystalline diamond tips and cemented carbide substrates sintered at high temperature and high pressure. They can not only take advantage of diamond’s high hardness, high thermal conductivity, low friction coefficient, low thermal expansion coefficient, low affinity with metals and non-metals, high elastic modulus, no cleavage planes, isotropy, etc., but also take into account the high strength of cemented carbide.PCD tools include standard inserts, milling cutters, drills, tool inserts, grinders and combination tools, suitable for a variety of cutting and grinding processes

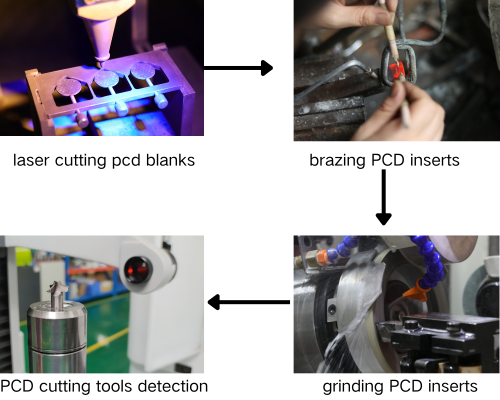

PCD Tool processing process

The production process of PCD tools includes cutting of PCD blanks,welding PCD blanks to cemented carbide substrate ,cutting tools grinding, quality inspection, etc.

Moresuperhard 's products for PCD Tools Manufacturing

1.PCD Blanks

We provide round PCD blanks and customized shape PCD blanks for various PCD cutting tools.

Round PCD blanks:maximun 72mm

Grit sizes:1μm,5μm,10μm,25μm,50μm suitable for different applications like metal cutting,wood working,cutting graphite and CFRP.

2.Brazing machine and brazing solder

Moresuperhard provide high frequency brazing machine and vacuum brazing machine sutible for different welding requirements.Sliver welding rod and brazing solder.

3.Vitrified diamond grinding wheel

6A2 vitrified bond diamond grinding wheel is most commonly used for grinding PCD inserts.But if you also produce PCD reamers and other PCD rotary tools,Our customer also purchased 1a1,3a1,14a1 pcd grinding wheel from Moresuperhard .

4.PCD grinding machine

Moresuperhard provide manual grinding machine and cnc grinding machine for grinding different PCD cutting tools.

Choose Moresuperhard,Choose high efficiency

Moresuperhard have many customer from PCD cutting tools industry.Therefore,we have rich experience in procrssing PCD cutting tools and PCD raw materials.We can provide all the consumables needed to produce PCD tools.

Recommended specifications of commonly used PCD blanks and vitrified diamond grinding wheels

PCD blanks for inserts and reamers

8 X 10 X R4 X thick 1.8

15 X 4.2 X R3 X thick 1.8

6 X 4 X R2 X thick 1.6

6 X 10 X R5 X thick 1.8

10 X 3.2 X R3 X thick 1.6

8 X 3 X R2 X thick 1

10 X6 X R3 X thick 1.8

10 X 6 X thick 1.6

5 X 3 X thick 1

6 X 2.8 X R2 X thick 1

Vitrified diamond grinding wheel

3A1. D150xH32xU2xX10

11A2.D150×H32xT40×W5×X10 #1000

6A2. D150xH32xT40xW10xX10 #500

6A2. D150xH32xT40xW10xX10 #1000

6A2. D150xH32xT40xW20xX10 #1000

What kind of products do you need?Please contact us freely

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088