Grinding characteristics of diamond tools - how to correctly select the grinding crystal plane and crystal orientation

Wide application of single crystal diamond tools in the field of ultra-precision machining

Ultra-precision cutting is an important field in ultra-precision machining, and it is a new technology with a wide range of contents. Using precision single crystal diamond tools to process non-ferrous metals and non-metals can directly cut out ultra-smooth processing surfaces, which can replace ultra-precision grinding and other finishing processes, greatly improving processing efficiency and ensuring processing accuracy and surface quality. In recent years, single crystal diamond tools have penetrated into various fields of machining and played an increasingly important role. The high hardness and good wear resistance of diamond make diamond an ideal tool material, but at the same time, the problem of difficult grinding of single crystal diamond tools is gradually emerging.

Sharpening characteristics of single crystal diamond tools

In ultra-precision machining, the two basic accuracies of single crystal diamond tools are the edge profile accuracy and the blunt radius of the edge. It is required that the roundness of the arc tool edge for processing aspheric lenses is less than 0.05 μm, and the straightness of the edge for processing polyhedral mirrors is 0.02 μm; the blunt circle radius (ρ value) of the tool edge indicates the Sharpness, in order to meet various processing requirements, the radius of the blade edge ranges from 20nm to 1μm.

Crystal Face Selection of Single Crystal Diamond Tools

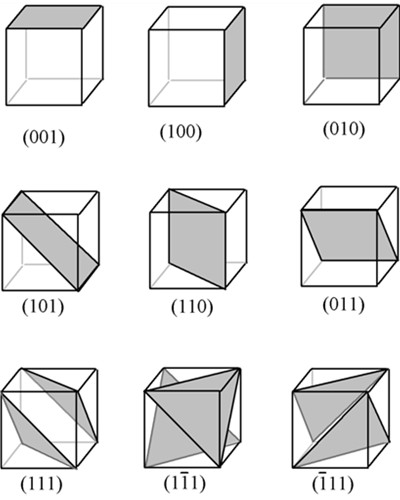

Diamond crystals belong to the cubic crystal system. Due to the difference in atomic arrangement and atomic density on each crystal plane and the distance between crystal planes, the anisotropy of natural diamond crystals is caused. Therefore, diamond not only exhibits physical and mechanical properties of each crystal plane Different, its manufacturing difficulty and service life are not the same, and the microscopic damage strength of each crystal plane is also significantly different.

The microscopic strength of diamond crystals can be measured by the Hertz test method. Since diamond is a typical brittle material, its strength value generally has a large deviation, which mainly depends on the shape and distribution range of the stress distribution, so it is suitable for analysis by probability theory.

When the applied stress is the same, the (110) crystal plane has the highest damage probability, followed by the (111) crystal plane, and the (100) crystal plane has the smallest damage probability. That is, under the action of external force, the (110) crystal plane is the most vulnerable to damage, followed by the (111) crystal plane, and the (100) crystal plane is the least likely to be damaged. Although the grinding rate of the (110) crystal plane is higher than that of the (100) crystal plane, the experimental results show that the (100) crystal plane has higher resistance to stress, corrosion and thermal degradation than other crystal planes. Considering the comprehensive consideration of microscopic strength, using the (100) surface as the front and rear cutter faces of the tool can easily sharpen the high-quality cutting edge and is not easy to produce microscopic chipping. Generally, the crystal face selection of single crystal diamond tools should be carried out according to the requirements of the tools. Generally speaking, if the diamond tool is required to obtain the highest strength, the (100) crystal plane should be selected as the front and flank of the tool; if the diamond tool is required to resist mechanical wear, the (110) crystal plane should be selected as the front and back of the tool If the diamond tool is required to resist chemical wear, the (110) crystal plane should be used as the rake face of the tool, the (100) crystal plane should be used as the flank face, or the (100) crystal face should be used for both the front and flank faces. These requirements need to be realized with the help of crystal orientation technology.

Orientation method of diamond tool

1.Manual visual inspection of crystal orientation

Artificial visual inspection is based on the external geometry of natural crystals, surface growth, corrosion characteristics, and the geometric angle relationship between each crystal plane, relying on the operator's long-term work experience, rough crystal orientation through observation and experimentation. This method is simple, easy to implement, and does not require equipment, but the accuracy of the orientation results is poor, requiring high operator experience, and manual visual orientation cannot be performed on tools that have been processed and have lost the characteristics of natural single crystal.

2.laser crystal orientation

Laser crystal orientation is to irradiate the surface of the diamond crystal with a laser with good coherence, and the regular crystal grains and microscopic pits formed on the surface during the growth process in different crystallographic directions are reflected on the screen to form features. Diffraction light image. But in fact, due to external interference factors, the naturally formed regular crystal grains and microscopic pits are often not obvious or cannot be observed at all. Therefore, before the crystal is oriented, it must undergo appropriate artificial corrosion to form a characteristic shape.

3.X-ray Crystal Oriented Diamond

The diamond is irradiated with X-rays, and the jig holding the diamond is rotated so that the 4th, 3rd, or 2nd symmetry axis of the diamond coincides with the direction of the incident X-ray beam, and a symmetrical diffraction image appears. Since the wavelength of X-rays is close to the lattice constant of the crystal, diffraction occurs when X-rays pass through the crystal or reflect back from the surface of the crystal. Using this principle, a dedicated X-ray crystal orientation instrument has been developed. This crystal orientation method has high precision, but since X-rays are harmful to the human body, it is necessary to pay attention to the protection of the operator when using it.

Crystal orientation selection of diamond tools

Diamond is anisotropic, so not only the hardness and wear resistance of each crystal face are different, but also the wear resistance of the same crystal face in different directions is also different. If the crystal orientation is not selected properly, even if the crystal plane is selected correctly, the sharpening efficiency will be greatly reduced. At the same time, since the compressive strength of diamond crystals is 5 to 7 times greater than the tensile strength, it is necessary to choose the easy-to-grind direction of the crystal surface during the sharpening process, and at the same time, the cutting edge should face the positive direction of the linear speed of the grinding wheel (that is, take back grinding) to ensure sharpening efficiency and reduce the degree of microscopic cleavage of the cutting edge. Grinding of diamond tools Grinding includes rough grinding and fine grinding. During rough grinding, the easy-grinding direction of the crystal should be selected; the rough grinding of diamond tools is related to the grinding direction, grinding speed and pressure, and the particle size of the diamond powder used.

Chipping Phenomenon During Diamond Tool Grinding

The wear mechanism of diamond tools is relatively complex, which can be divided into macro wear and micro wear. The former is mainly mechanical wear, and the latter is mainly thermochemical wear. Common diamond tool wear damage forms are rake face wear, flank wear and edge cracking. In the sharpening process of single crystal diamond tools, its wear is needed to sharpen the tools that meet the requirements, but if unnecessary wear occurs, it may damage the sharpened front and flank surfaces. The edge cracking (that is, chipping) occurs when the stress on the edge exceeds the local bearing capacity of the diamond tool, and is generally caused by microscopic cleavage damage of the diamond crystal along the (111) crystal plane. In ultra-precision machining, the radius of the blunt circle of the cutting edge of the diamond tool is relatively small, and it is also a hard and brittle material. The impact of the mouth, so it is often accompanied by chipping.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088