Wire-drawing die project solutions

What is the wire drawing ?

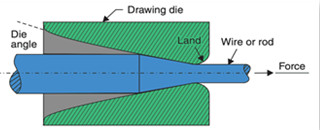

In Metal produce With external force to make carbon steel, stainless steel, aluminum, copper and other metals forced through the dies, its cross section is compressed into the required shape and size, Under the action of drawing force, the wire rod or blank is drawn from the die hole of the drawing die to produce steel wire or non-ferrous wire with small section. All kinds of metal and alloy wire of different section shape and size can be produced by drawing. this is our common wire drawing process.

What is wire-drawing dies?

Wire drawing die is the most important tool in metal wire production. In the metal wire production process, the metal wire is through the drawing die deformation to reach the predetermined dimensional accuracy and surface finish, die material, die hole geometry, the structure of the drawing die and the working mode directly affect the quality of the metal wire and production efficiency.

Drawing dies of several commonly used materials

1.TC drawing dies(tungsten carbide)

·Good for ferrous rod-size wire

·Good for short and trial runs

·Low - cost

·Carbide grade tailored to wire material for different wire material

·Special coatings available to reduce friction and/or increase durability

2.PCD drawing dies

·Much long use life than TC

·Suitable for long production runs

·Best choice for highly corrosion wire materials

·Suitable for titanium wire materials

·Wire remains round, even with significant die wear

3.MCD drawing dies

·Good for fine and super fine wires

·Low surface friction

·Smooth wire surface

·Ultra-high accuracy wire available

Cold drawing and hot drawing

The types are divided according to the temperature of the metal at the time of drawing. The drawing below the recrystallization temperature is cold drawing, the drawing above the recrystallization temperature is hot drawing, and the drawing below the recrystallization temperature is warm drawing. Cold drawing is the most common drawing method used in wire and wire production. During hot drawing, the metal wire should be heated before entering the die hole. It is mainly used for drawing the high melting point metal wire such as tungsten and molybdenum. During warm drawing, the metal wire also needs to be heated by the heater to the specified range of temperature before entering the die hole for drawing. It is mainly used for drawing zinc wire, refractory alloy wire such as high-speed steel wire and bearing steel wire.

Problems and solutions when drawing production

1.wire discoloration

Wire (such as copper) surface discoloration is mainly oxidation discoloration, resulting from improper temperature and humidity conditions. It may be that the emulsion concentration is too low or the temperature is not normal; Wire attached too much oil; Substandard water quality; Foreign oil mixed, etc.;

2.High wire die loss

One of the reasons leading to large die loss is the improper operation of the machine, the other is the wrong choice of lubricant. If the machine is not running properly, the operator needs to practice constantly and check its working condition before each run. In addition, lubricant plays a key role in assisting and promoting the drawing process, and its selection is very important.

3.Broken line scratches and burrs

The broken line scratches and burrs of the wire greatly affect the beauty and quality of the product. The cause of these problems may be the pollution of metal scraps, the blockage of mold holes or the aging of lubricants caused by direct contact between metal and mold due to insufficient lubrication. These problems can be solved by removing metal scraps, removing blockages and replacing lubricants by filtering equipment.

4.Excessive emulsion stratification/surface precipitates

The invasion of microorganisms, PH is too low, the hardness of water and inorganic salts in the mixture is too high, and the temperature of the emulsion is too high, which may cause the emulsion stratification or excessive precipitates on the surface of the wire. If it is microbial damage, you can add fungicide, and add sodium hydroxide solution or triethylamine alcohol; Too low PH also need to supplement sodium hydroxide solution or triethylamine alcohol; When the hardness of water and inorganic salts are too high, it is necessary to replace the water. The emulsion temperature is too high, it needs to be properly cooled before use.

Moresuperhard provide PCD and MCD wire-drawing dies for you ,if you are interested in our products,please conatct us freely.

Email:pcd@moresuperhard.com

Whatsapp:+86 17700605088

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088