What is die core?

The mold core refers to the precision part used for the critical operation of the center part of the mold. The general structure of the mold core is extremely complex, the processing is very difficult, and the cost is very high. Often the labor expenditure for manufacturing is much greater than the material itself. The choice of mold core material is directly related to the cost of the mold and the service life of the mold.

What are the common die core materials?

The materials used for general processing mold cores are P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136, etc., and the materials for hardened molds are 2344, 8407, SKD11, SKD61, etc.

The applications of optical die core

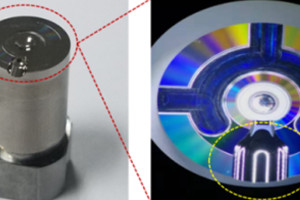

Optical lenses are generally called camera lenses or photographic lenses, referred to as lenses, and their function is optical imaging. The optical lens is an essential component in the optical imaging system, which directly affects the quality of the imaging and affects the realization and effect of the algorithm. The forming of precision optical lenses requires high-level technology and equipment in terms of mold design, mold core processing, forming conditions and lens measurement.

In recent years, the scope of application of plastic lenses has continued to increase. The lenses required by the optical system have a small radius of curvature, high precision, and a large thickness ratio, which further increases the difficulty of molding technology. Taking plastic lenses as an example, during the molding process of plastic lenses, the plastic needs to be taken into the mold, and then it is completed in three steps: filling, pressure holding, and cooling. Therefore, the foundation of precision injection molding lies in high-precision molds. The quality of the mold is the key to the lens forming technology, and it is also the most expensive part in the entire lens manufacturing process. As the core of a set of molds, the die core is also the part with the greatest added value. The more precise the mold core, the higher the shape accuracy of the lens will be.

How to process optical die core?

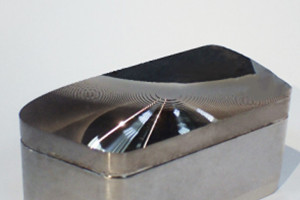

The processing of the mold core is completed by multiple very precise processes. The processor must clearly understand the shape of the contour, be familiar with the surface contour measurement technology, and have a considerable knowledge of machining in order to turn out a high-precision mold core. At present, the surface shape error of the small-aperture aspheric lenses used in imaging lenses in the industry can be processed to less than 0.1um, and the RA (surface roughness) can reach 0.05um.

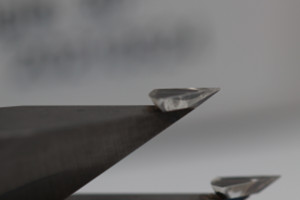

CVD diamond tools for processing optical die core

The uniform crystal structure of single crystal diamond without internal grain boundaries makes the cutting edge of the tool theoretically reach atomic-level straightness and sharpness. CVD diamond cutting tools has strong thinning ability, high precision and low cutting force during cutting.The degree of hardness is extremely small, the cutting edge is free of defects, the machined surface can achieve a mirror effect, and its surface roughness can reach below Ra-0.1μm. the high hardness of single crystal diamond, good wear resistance, corrosion resistance and chemical stability can be guaranteed the cutting tool has an ultra-long life, so that it can carry out continuous cutting for a long time, and can reduce the impact of tool wear on the precision of the part; the high thermal conductivity of the single crystal diamond tool can reduce the cutting temperature and the thermal deformation of the part.

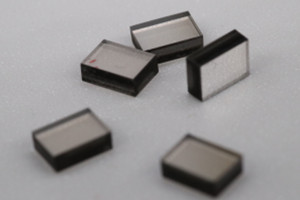

Moresuperhard provide quality CVD diamond plate for optical diamond cutting tools

It can provide high-quality CVD single crystal diamond products of various sizes (≤20mmx20mmx10mm), and the appearance and shape can be customized.

Diamond grinding wheel for grinding precison single crystal diamond cutting tools

Moresuperhard is always focus on providing grinding products and grinding solutions for superhard materials like PCD/PCBN/MCD/CVD and others.Morehard have develpoed a mature grinding paraments for single crystal diamond tools.Please contact us to learn more details.

Customized diamond grinding wheel for Corborn SCD grinding machine.Other diamond grinding wheel for grinding single crystal diamond tools please contact us freely.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088