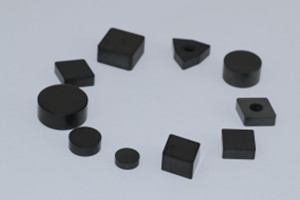

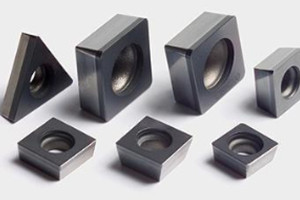

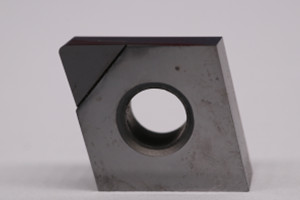

Common Indexable insert materials

Carbide, PCD, PCBN, ceramics, cermet

How to choose the appropriate abrasive grinding wheel according to the tool material?

There are many kinds of cutting tools materials,It is very important to choose suitabel grinding wheel.Moresuperhard recommand suitable grinding wheel for your workpieces.

| Diamond Grining Wheel | Carbide, non-ferrous metals, Polycrystalline diamond (PCD) ,cermet or ceramic ,Polycrystalline cubic boron nitride (PCBN) |

| CBN Grinding Wheel | tool steel, high speed steel |

Indexable inserts grinding procession

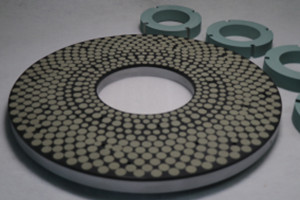

Surface grinding

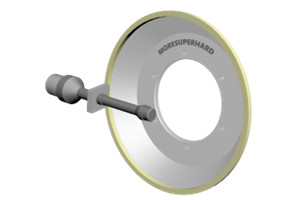

Double end grinding disc is suitable for batch of grinding the surface of indexable inserts.The upper and lower end surfaces of the inserts can be processed at the same time, with high grinding efficiency, which can effectively improve production efficiency.After grinding, the workpiece has good consistency and high grinding accuracy.

Grinding wheel mold:2A2T、12A2B、11A2、11A2B、11A2T、6A2BT、6A2H、6A2M

Suitable double end grinding machine:PETER WOLTERS、Melchiorre、Stahli、Lapmaster、AM Technology

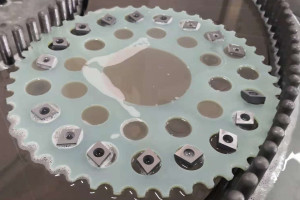

peripheral grinding &chamfer grinding

Vitrified bond diamond peripheral grinding wheel and resin diamond peripheral grinding wheel for peripheral grinding PCD/PCBN/carbide/cermet indexable inserts.Moresuperhard provide peripheral grinding with the feature of good surface accuracy retention, high material removal rate, good wear resistance, high durability, and good blade edge quality after processing.

Grinding wheel mold:6A2T, 6A2M, 11A2B, 12A2T,11A2

Suitable peripheral grinding machine:Agathon,Ewag,Waida

chip breaker grinding

The role of cutting tool chipbreakers

◇Cut off chips without entanglement.

◇Control the outflow direction of chips and maintain the accuracy of the machining surface.

◇Reduce cutting resistance and extend tool life.

If you have any questions about grinding indexable inserts including PCD/PCBN/carbide/ceramic/cermet inserts,please contact us freely.Moresuperhard provide resin bond and vitrified diamond peripheral grinding wheel for your indexable inserts.Customized grinding wheel according to your grinding machine and inserts need to be processed.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088