In the field of hard turning, PCBN polycrystalline cubic boron nitride inserts occupy a large proportion. PCBN inserts are widely used in hard turning due to their high hardness, good wear resistance, strong chemical stability, and excellent thermal conductivity. .

Proper selection and application of tool edge treatments are considered to be one of the essential elements for the successful manufacture and proper use of hard turning tools. For different application conditions, cutting edge processing has different processing forms and parameters. Tool edge treatment refers to a process after the blade is finely ground and before the coating (if any), by chamfering, passivating, flattening, polishing and other treatments on the cutting edge, so as to improve the quality of the tool and prolong the service life of the tool.

What is PCBN inserts edge ?

The cutting edge of the tool refers to the interface between the rake and flank faces of the insert, where the workpiece material separates to form chips and machined surfaces. Tool edge treatment is to improve the quality of the tool and increase the service life of the tool by chamfering, passivating, flattening and polishing the edge after the blade is finely ground.

Why is the cutting tools edge treated

After the PCBN insert is sharpened by a diamond grinding wheel, there will often be a certain degree of microscopic gaps on the cutting edge, such as micro chipping, sawing, etc. During the cutting process, the microscopic notch on the cutting edge of the tool is easy to expand, which will accelerate the wear and damage of the tool. In order to eliminate the microscopic defects of the edge during processing, edge treatment is required. After the edge treatment of the PCBN inserts, the cutting tool edge can be strengthened, and the wear resistance of the tool can also be improved, thereby prolonging the tool life.

PCBN indexable inserts are usually ground with a ceramic-bonded diamond wheel. For ceramic bonded silicon carbide or corundum grinding wheels, the wheel ring must be continuously dressable during processing to keep the diamond wheel flat and sharp for stable grinding.

It is an economical method to divide the grinding process into rough and fine grinding. During peripheral grinding of indexable inserts, the use of a wheel ring with larger abrasive grains can effectively remove material from the insert. The protective chamfer is then ground with a grinding wheel ring containing a smaller grain size. Typically, smaller diamond particles produce small chipping (chipping) at the cutting edge, but require longer machining times due to their lower feed rates. The perfect combination of high-efficiency material removal during grinding and small chipping during chamfering.

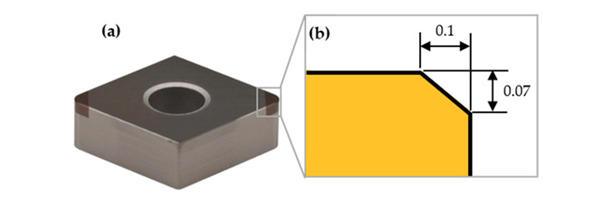

Moresuperhard Products Co., Ltd can provide vitrified/ ceramic and resin diamond grinding wheels for grinding PCBN chamfers. Vitrified/ Ceramic diamond grinding wheel is used for grinding PCBN chamfer. Below is the drawing provided by the customer.

On this basis, we have improved the drawings. Customized grinding wheels for customers. Make the design more in line with production requirements and usage requirements.

In addition to customization, we also provide standard 6A2 resin diamond grinding wheels for PCBN chamfer grinding, and the coarse grinding grit W35 has also received very good feedback from customers in practical applications.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088