What is polycrystalline diamond PCD

Polycrystalline diamond (PCD) is a polycrystal formed by mixing micron-sized diamond powder with a small amount of metal powder (such as CO) and sintering at high temperature (1400°C) and high pressure (6000MPa). The disordered arrangement of diamond grains gives PCD uniform, extremely high hardness and wear resistance. Compared with other tool materials, polycrystalline diamond has the following performance characteristics:

1. Extremely high hardness and wear resistance

2. High thermal conductivity and low thermal expansion coefficient, fast heat dissipation during cutting, low cutting temperature, and small thermal deformation

3. Friction coefficient Small, can reduce machined surface roughness

PCD can be used for cutting tools, grinding wheel dressing, geological drilling, measuring tool probes, wire drawing tools, sandblasting tools, etc. However, the high hardness and high wear resistance of PCD also bring great difficulties to its processing.

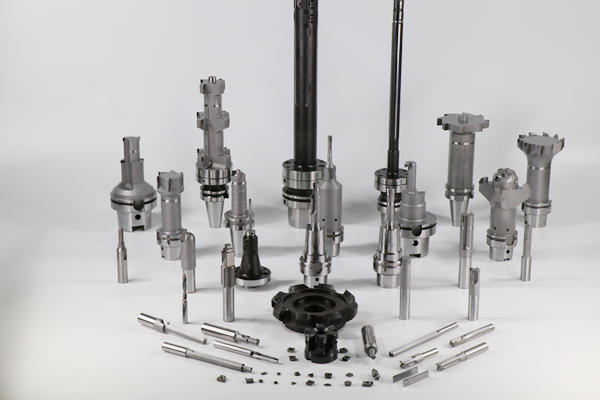

PCD tools show excellent cutting performance in high-speed cutting of non-ferrous metals and their alloys and non-metallic materials, so they have been widely used in automotive, aviation, aerospace, building materials and other industrial fields

Manufacturing process of PCD tool

The production process of PCD cutting tools generally includes polishing, cutting, fixing, sharpening, quality inspection, etc. The diameter of the PCD superhard material blank is usually 1/2, 1, 2, 3, and 4 inches, and its surface is generally rough (Ra2 ~ 10μm), which cannot be directly used to make tools, and needs to be ground and polished to make the surface reach a mirror surface (Ra). ≤0.01μm), and then processed into a blade of a certain geometry and size by laser cutting or wire electric discharge cutting, and then further mechanical and chemical treatment of the blade and the surface to be fixed on the substrate, and then silver-based brazing to cut the blade. It is fixed on the base and finally sharpened by a diamond grinding wheel.

The processing methods of diamond (PCD) tools are generally divided into three types: grinding, EDM and cold laser processing.

However, comprehensive analysis found that these processing technologies are currently mostly suitable for rough processing of PCD materials. In order to obtain good PCD cutting edge quality, the most ideal processing method is still grinding with a diamond grinding wheel. Diamond grinding wheel mechanical grinding is the most widely used PCD tool grinding method. 0.02min3/min3), but good cutting edge quality and complete and smooth front and flank surfaces can be obtained. One of the keys to PCD cutting tool manufacturing technology is the sharpening quality of the cutting edge. The lack of ideal sharpening process and technology for high-quality tool head materials will result in waste of resources. Adopting a good sharpening process will improve the product quality of the tool and reduce the cost of tool use.

Process selection of grinding wheel sharpening pcd tool

One of the purposes of cutting tool sharpening is to obtain cost-effective cutting edge quality, and the key to quality is the choice of grinding wheel particle size. The vitrified / ceramic diamond grinding wheel developed and produced by Moresuperhard is used for rough and fine grinding of superhard tools such as PCD/CBN, MCD, CVD, etc. The finer the grinding wheel, the smaller the chipping of the cutting edge and the lower the grinding efficiency. The PCD cutting tools sharpening process is divided into three processing stages: rough, medium and fine. According to the specific situation, formulating a reasonable sharpening process can greatly improve the processing efficiency.

Classified according to the precision and use of the cutting edge

Serial number - cutting edge accuracy - optional grinding wheel particle size - use

a Rough—0.05mm—230/270#~320/400#—rough machining

b Medium — 0.02mm—M20~M40—Semi-finishing

c Fine —0.005mm—M5~M10—finishing

Classification according to the degree of blade failure (regrinding tool)

Serial number - degree of failure - optional grinding wheel particle size - remarks

a Rough—the cutting edge is damaged by 0.5mm—230/270#~320/400#—or EDM

B fine - cutting edge chipping 0.3mm - M20 ~ M40

c thin - cutting edge wear 0.1mm - M5 ~ M10

Rough machining does not require high cutting edge, and electrical machining or grinding can be selected. Electric machining has high efficiency and is suitable for processing complex tools, such as drills for printed circuit boards, forming milling cutters for cutting laminate floors, etc. Coarse-grained grinding wheel is optional for grinding, with large contact area and high grinding force (300-400N) during sharpening, which can quickly remove excess machining allowance; fine-grained grinding wheel is selected for fine-grained grinding, with small contact area during sharpening , Low grinding force (100 ~ 200N), low grinding heat, but low material removal rate. This stage is mainly through grinding and polishing to further improve the quality of the cutting edge. Finishing resides in the two.

The grinding process of PCD is mainly the result of a mixture of mechanical and thermochemical aspects. The mechanical action is the micro-breaking, wear, shedding or cleavage of the diamond formed by the continuous impact of the diamond grinding wheel abrasive particles on the PCD material; the thermochemical action is that the high temperature formed by the diamond grinding wheel grinding PCD causes the diamond to oxidize or graphitize. As a result of the mixed action of the two, the PCD material is removed.

PCD grinding processing characteristics are mainly

1. Great grinding force

Diamond is the substance with the highest hardness among the known minerals, and the wear amount of friction with various metals and non-metallic materials is only 1/50~1/800 of that of cemented carbide; the hardness (HV) of PCD is 80~120KN/mm2 , second only to single crystal diamond, much higher than cemented carbide. When grinding PCD with diamond grinding wheel, the initial cutting strength is very high, which is about 10 times that of cemented carbide (0.4MPa); the specific grinding capacity is 1.2×104~1.4×105J/mm3; therefore, the grinding force is much higher For grinding carbide.

2. The grinding ratio is very small

Due to the high hardness and wear resistance of PCD (the relative wear resistance is 16 to 199 times that of cemented carbide), the grinding ratio of PCD is only 0.005 to 0.033, which is about 1/1000 to 1000 of that of cemented carbide. 1/100000; grinding efficiency is only 0.4~4.8mm3/min. Therefore, in order to ensure the cutting edge quality and removal amount of the cutting tool, the grinding time is very long and the processing efficiency is very low. In addition, when the hardness, content and particle size of PCD are different, the grinding time is also very different.

3. The particle size has a great influence

PCD materials used in cutting tools are mainly divided into three categories according to particle size: coarse particle size (20 ~ 50μm), medium particle size (about 10μm) and fine particle size (~5μm). The grinding force and grinding ratio are different from several times to dozens of times times. Coarse-grained PCD has the highest grinding ratio and is the most difficult to grind. After grinding, the cutting edge has the most serious serration and the worst quality, but the wear resistance is the strongest; The cutting edge quality is the best after grinding.

More SuperHard can supply quality vitrified diamond grinding wheel with long life as well as fast cutting. We only choose the very strong synthetic diamond as the raw materials, we make sure not only the particle shape is round enough but also be with some sharp points, which can make sure we won't lose the efficiency while we still want enough life from the wheels. So it will help you get fast, stable, much more PCD tools in unit time.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088