What is ferrite core?

Ferrite is a special ceramic material, mainly composed of iron and oxygen, with high magnetic permeability and low electrical conductivity. The magnetic core made of this material is what we call ferrite core.

Characteristics of ferrite cores

1. High-frequency performance: Due to the characteristics of ferrite, it performs well in high-frequency applications and reduces core losses.

2. High magnetic permeability: Ferrite cores are able to effectively concentrate and conduct magnetic fields, which means they can achieve the same performance in a smaller volume.

3. Thermal stability: Compared with other magnetic materials, ferrites still maintain their magnetic properties at high temperatures.

Applications of ferrite cores

1. Power electronics: In transformers, inductors and filters, ferrite cores provide high-efficiency and small-volume solutions.

2. RF and communications: Ferrite cores are widely used in RF transformers, impedance matching and electromagnetic shielding.

3. Data storage: Some hard drive technologies use ferrite cores to enhance storage density and performance. 4. Electromagnetic interference (EMI) filtering: Ferrite rings or beads are used to wrap cables to suppress and reduce electromagnetic interference.

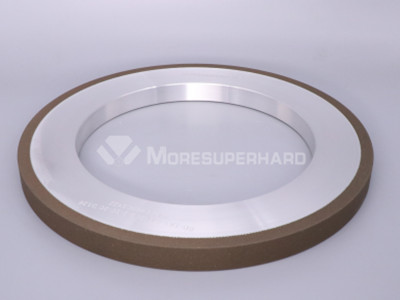

what kind of grinding wheels is suitable for grinding Ferrite core?

Diamond grinding wheels can grind hard-to-process materials such as soft ferrites, hard alloys, glass, and ceramics at high speed. Diamond has high wear resistance, less wear on the grinding wheel, and longer service life. In the grinding process, the size and shape of the diamond grinding wheel change little, which is suitable for high-precision processing. The thermal conductivity of the diamond grinding wheel is very good, which is conducive to the evacuation of heat, avoiding the phenomenon of core burns, cracks, and falling blocks, improving the quality of the core surface processing, and at the same time high production efficiency.

How to choose diamond grinding wheel for grinding ferrite?

Usually, resin bond diamond grinding wheels and metal bond diamond grinding wheels are used for grinding soft ferrites, among which resin bond diamond grinding wheels are the most commonly used. The size of the grain has a direct impact on the surface quality, grinding efficiency, and tool loss of the workpiece. Soft magnetic materials are easy to clog the pores of the grinding wheel, so choose a grinding wheel with a small grain size. When the hardness of the magnetic material is high, choose a grinding wheel with a large grain size.

Ferrite core grinding parameters

The selection of grinding parameters directly affects the surface quality of soft ferrite workpieces, among which feed rate is the greatest influencing factor.

Rough grinding ferrite core

In the initial grinding stage, when the grinding wheel begins to contact the workpiece, due to elastic deformation, the actual cutting amount is smaller than that displayed on the grinder dial. A larger radial feed rate can be used to improve work efficiency. At this time, there is vibration during processing, the workpiece has low precision, large surface roughness, and large surface residual stress, which can easily cause surface deformation and burns, and edge breaking, chipping, and cracking of soft ferrite workpieces. Therefore, in the initial grinding stage, the grinding feed rate should be reasonably selected. Generally, the feed rate is 0.01-0.02 mm/time and can be fed continuously. The feed rate should be large at first and then small to prevent deep scratches or edge breaking and chipping that are difficult to eliminate in subsequent processing.

Fine grinding ferrite core

In the stable grinding stage, the actual cutting depth is the same as that displayed on the grinder dial. At this time, the radial feed is reduced to improve the surface quality of the workpiece. The workpiece has higher precision, smaller surface roughness, and smaller surface residual stress. The feed is 0.005 mm/time. In the light grinding stage, in order to improve the grinding accuracy and surface roughness, there is no radial feed or a very small feed, and the actual cutting depth is larger than that displayed on the grinder dial.

Common grinding wheel specifications for grinding ferrite cores

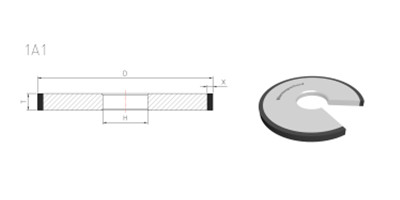

1A1 240*10*127*5*U U=10/12/13/14/15/17/20/24

1A1 300*15*127*5 *U U=15/17/20/24

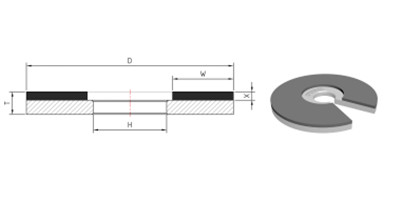

1A2 297*180*40*58.5*10

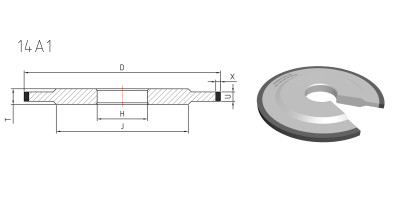

14A1 300*15*127*5*U U=5.5/6.5/8/9/10/12/14

14A1 240*10*127*58*U U=5.5/6.5/8/9

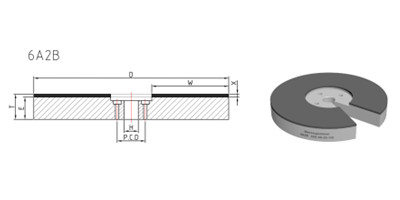

6A2 400*40*120*60*10

Ferrite is generally formed into blanks by sintering. The blanks are typical hard and brittle materials, which are difficult to process. The finishing process and processing parameters need to be optimized to ensure their quality. Due to its high hardness, high brittleness, heat sensitivity, and easy to burst when the temperature changes suddenly, the grinding of ferrite is very critical.Moresuperhard have rich experience in grinding ferrite core and we can provide customized diamond grinding wheels according to your grinding machine.Welcome your enquire.

<< :How to Dress Worm Grinding Wheels

<< :Differences between Carbide Milling Cutters and HSS End Mills

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088