Applications of worm grinding wheel

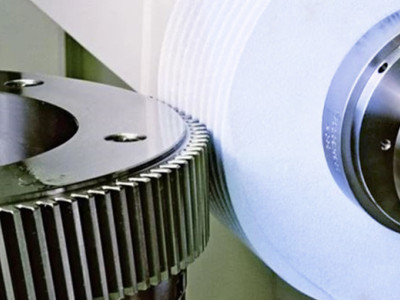

Worm grinding wheel is an important tool in the process of gear grinding, mainly used for grinding worms and worm wheels. It has a wide range of applications in the fields of automobiles, engineering machinery, aviation, etc.

Causes Grinding Wheel Loss

The wear of worm grinding wheels is mainly reflected in the diameter direction and axial direction. The wear in the diameter direction is mainly caused by grinding wheel dressing, which aims to remove the surface layer of the grinding wheel tooth surface that has been damaged or does not meet the processing accuracy requirements, similar to the grinding of hobs and razors. The wear in the axial direction mainly comes from the grinding wheel jumping, which aims to prevent the grinding wheel from repeatedly grinding the workpiece at the same position, resulting in the workpiece surface roughness not meeting the requirements or grinding burns.

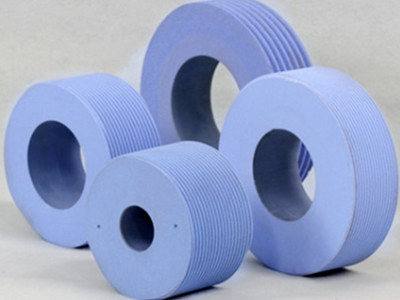

Dressing solutions for worm grinding wheel

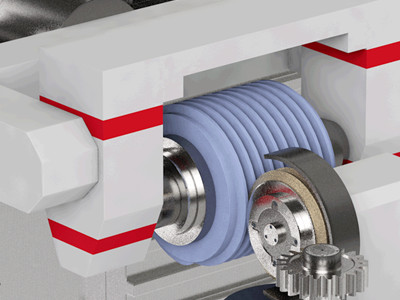

In order to ensure the grinding efficiency and accuracy of the worm grinding wheel, the dressing of the grinding wheel is also an important part. There are mainly the following dressing methods:

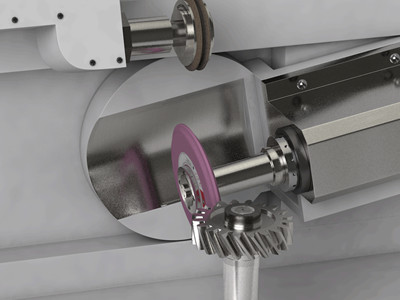

1. Regular dressing: Set a fixed time interval to dress the grinding wheel, such as dressing once after grinding a certain number of workpieces or dressing once after continuous work for a certain period of time. This method can repair the surface wear of the grinding wheel in time, remove the passivated abrasive, maintain the sharpness and dimensional accuracy of the grinding wheel, and improve the grinding efficiency and grinding accuracy.

2. Adjustment during grinding: This method is to dress by adjusting the position of the grinding wheel against the workpiece, mainly for the change of the surface shape of the grinding wheel. During the grinding process, the eccentricity of the grinding wheel spindle is adjusted to consciously accelerate the contact surface loss and change the shape of the grinding wheel to make it conform to the required gear shape. This method can shape the grinding wheel without stopping grinding and improve production efficiency.

3. Common problems and treatment methods: During the grinding wheel dressing process, some common problems may be encountered, such as uneven wear of the grinding wheel surface and cracks in the grinding wheel. For these problems, corresponding treatment methods need to be taken, such as replacing the grinding wheel, adjusting the grinding wheel speed, etc., to ensure the normal use of the grinding wheel.

Selection of dressing tools: diamond dressing pen, diamond roller, etc.

Moresuperhard provide dessing solutions and diamond dressing tools for worm grinding wheel.if you need diamond dresser and diamond roller,please contact us freely.

A technical guide to selecting diamond grinding wheels for PDC cutter . Learn how ceramic and resin bond diamond wheels improve efficiency, precision, and tool life in oil & gas and mining applications.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088