Due to the high hardnes, PCD easy to produce high temperature in the process of machining, while high hardness leads to poor grinding efficiency,PCD is really difficult to grind materials.

How to choose abrasive for grinding PCD?

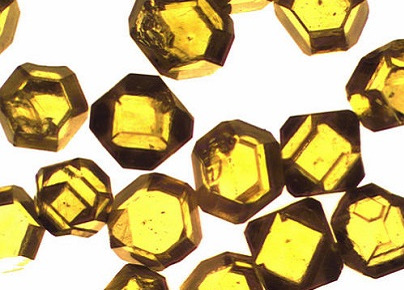

For machining PCD, we should choose material with high hardness,so diamond and CBN is ideal material for machining PCD.

Which kind of Bond grinding wheel is the ideal material for grinding PCD?

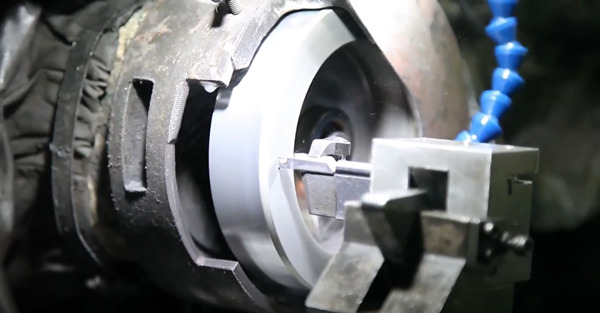

Most superabrasive grinding wheel are resin bond, while ceramic bond is more suitable for PCD material. Because the ceramic bond sintering can produce more pores, and the ceramic bond has advantages of good heat resistance and sharp cutting, so vitrified diamond grinding wheel is not easy to heat and expansion.

When grinding high hardness with vitrified diamond grinding wheel, grinding efficiency and precision will be higher than common resin diamond grinding wheel. Therefore, when machining PCD materials, the most suitable choice is to use vitrified bonded grinding wheels.

Suitale for PCD/PCBN cutting tools coarse/middle/finish and ultra-finish. In addition to grinding PCD/PCBN standard cutting tool, vitrified diamond grinding wheel also can grind PCD milling cutter, reamer and other custom tools

Advantages of Moresuperhard vitrified diamond grinding wheel:

1. The porous structure of the abrasive layer makes the passivated diamond fall off faster, which can prevent vertical lines on the workpiece and improve the surface quality.

2. Perfect dimensional tolerance control, suitable for CNC and manual grinder.

3. Good self sharpening, high grinding efficiency, high wear resistance, low abrasive consumption.

4. PCD/CBN tool can achieve good surface finish after grinding with vitrified diamond grinding wheel, avoid cutting edge breakage, reducing the scrap rate, improve the precision of PCD/CBN tool.

5. The life of Vitrified diamond grinding wheel is 10 times than resin bond diamond grinding wheel,can achieve dressing online easily.

|

Corase |

W40(D35),W28(D20) |

Perfect grinding forcr,suitable for coarse grinding cutting tool,high surface material removal rate |

|

Semi-finish |

W20(D20) |

Surface material removal rate and surface quality is good |

|

finish |

W10(D15A),W7(D15B) |

Good surface quality, cutting edge without debris |

|

Ultra-finish |

W5(D7)

W3.5(D3) |

Suitable for high-end customer pursuit high precision and ultimate surface quality and best quality |

|

Other specification and grit can customize accoring to your requirement |

||

---EDITOR: Cindy Chen/Doris Hu

---POST: Doris Hu

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088