Grinding

Home / Grinding / PCD Grinding Wheel > Vitrified Diamond Grinding Wheels

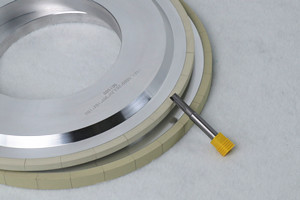

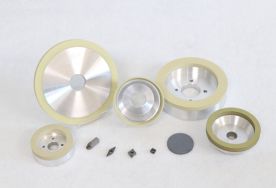

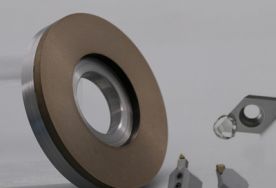

Vitrified bond Diamond Wheels and Tools

Vitrified Diamond Wheels Suppliers

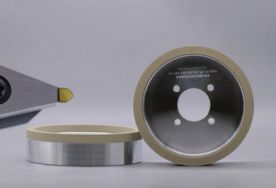

- Grinding, sharpening PCD &PCBN tools, tungsten carbide, ceramic, cermet, steel

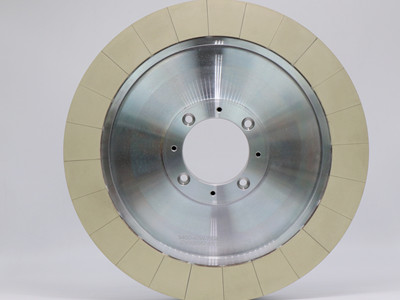

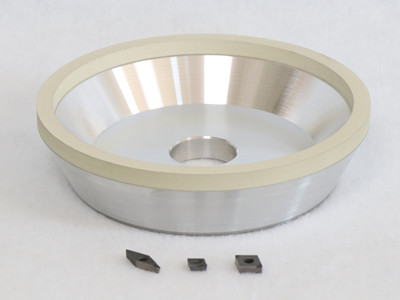

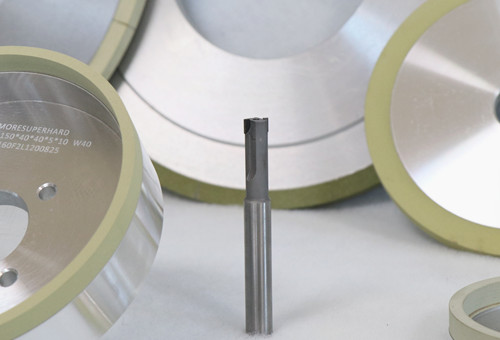

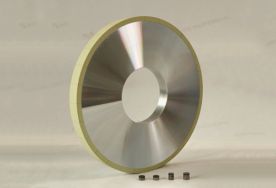

- Model of Vitrified grinding wheels: 1a1, 1f1, 6a2, 11v9, 2a2t, 6a9, 6a2t, 12a2t

What is a vitrified diamond grinding wheel ?

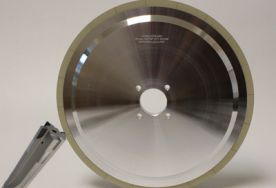

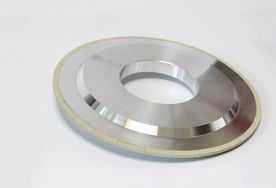

Vitrified diamond grinding wheels combine the hardest known super abrasives held mechanically and chemically in glass (ceramic bond) to form some of the most highly efficient grinding products available on the market. Vitrified bond diamond grinding whee is a kind of circular bonded abrasive with through-hole in the center which made of diamond powder and vitrified (ceramic) bond. Diamond grinding wheel is composed of the diamond layer, transition layer and matrix.

More SuperHard can supply quality vitrified diamond grinding wheel with long life as well as fast cutting. We only choose the very strong synthetic diamond as the raw materials, we make sure not only the particle shape is round enough but also be with some sharp points, which can make sure we won't lose the efficiency while we still want enough life from the wheels. So it will help you get fast, stable, much more PCD tools in unit time.

What are vitrified diamond grinding wheels used for ?

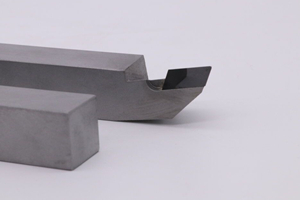

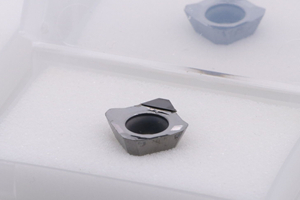

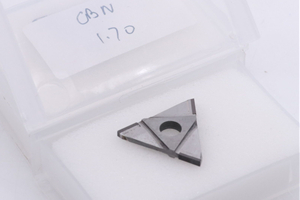

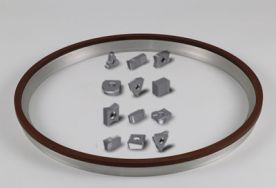

1. Vitrified grinding wheels most commonly employed in the grinding of PCD and PCBN tools and inserts. Cylindrical grinding, surface grinding, regrinding PCD cutting tools, PCBN cutting tools, CVD tools, MCD tools, ceramic tools, cermet tools, milling cutter, reamer, drill, etc.

2. Vitrified grinding wheels can also be used in the fabrication of natural diamond and diamond -like materials

3. Grinding ball screw, cast iron or steel parts such as injection nozzles, compressor blades and vanes,

4. Plus OD grinding of automotive and aerospace industry parts.

5. Ceramic material and composites, flame sprayed materials

Advantages of vitrified diamond wheels

- Because the PCD is made from the synthetic diamond, it's very very hard, usually we must use very high concentration diamond wheels like vitrified bond diamond wheels, which content 2 times synthetic diamond than resin diamond wheels in each cubic mm³. As we know, resin bond are always good at the carbide tools, but not PCD tools. Even that, when we use vitrified bond diamond wheel to grind PCD with 1000-6000# grit size even much more finer one, often we will remove almost as much stock from the wheel as comes off the PCD tools.

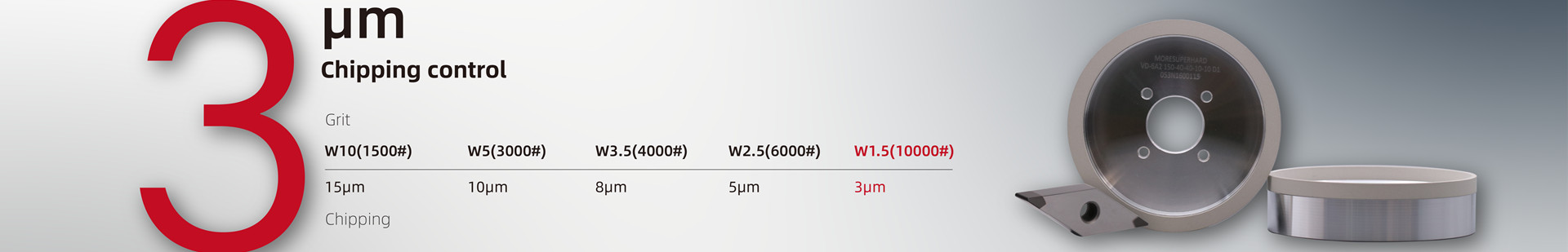

Grain size selection of vitrified diamond grinding wheel

| Grain Size | Machining Type | Application |

|

W40(500# D35) W28(D20) |

Rough | Regrinding a blade edge profile and sharpening of much worn inserts |

| W20 (800# -1000#, D20) | Universal |

Standard grain size also can get a high sharpening efficiency, good quality surfaces |

| W10 (1500# D15A) W7 (2000# D15B) | Finish | Finishing grinding - getting a very good quality of machined surfaces |

| W5 (3000# D7) W3.5 (4000# D3) | Super Finish | Super finish grinding - getting a brilliant quality of machined surfaces |

| Others grits of vitrified diamond wheel can be made according to customers' requirements. Email: pcd@moresuperhard.com | ||

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088