How to select the grinding wheel hardness of CNC cylindrical grinder

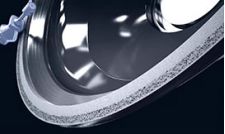

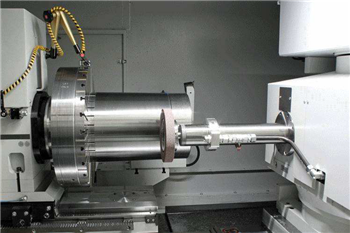

CNC cylindrical grinding machine is very common in die factory and hardware processing plant, and has become the common equipment of the majority of mechanical industry technicians, in the operation of the cylindrical grinding machine, the choice of abrasive is very important.

The harder the grinding roller surface, the softer the grinding wheel hardness should be.

(1) If the grinding wheel wears too fast, it means that the grinding wheel selected for the specific processing roller is too soft, the following improvement measures can be taken:

A. Improve the linear speed of the grinding wheel;

B. Increase the longitudinal feed speed of the towing plate, that is, increase the longitudinal feed of the workpiece to 2/3~3/4 of the width of the grinding wheel;

C. Reduce roll speed.

If the grinding effect is not obvious after taking the above measures, it indicates that the grinding wheel is too soft and not applicable, and a harder grinding wheel should be selected.

(2) if the grinding wheel is obviously blocked (labored) or dirty when grinding the roller, the passivating sand is not easy to fall off, the grinding wheel is easy to stick to the grinding debris, and the grinding roller surface is burned or brushed, then the grinding wheel selected is too hard and the following measures can be taken to improve:

A. Reduce the grinding wheel linear speed;

B. Increase roll speed.

If the grinding effect is not obvious after taking the above measures, it indicates that the grinding wheel is too hard and a softer grinding wheel should be selected.

<< Prev Article:CNC tool grinder diamond grinding wheel automatic dressing and compensation method

<< Next Article:Vitrified bond diamond grinding wheel for PCD saw blade grinding

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220