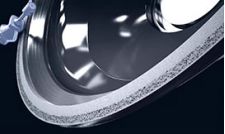

Vitrified bond diamond grinding wheel for PCD saw blade grinding

2019-12-09 15:28:25

Now I have a case about PCD saw blade sharpening. Customer is using Vollmer CHD270, a special and famous grinder for saw grinding and sharpening.

Customer is looking for vitrified bond diamond wheel and metal bond diamond wheel to mount on his grinder, the workpiece is PCD. To find a long working life is customer’s main requirement. Moreover, he does not have much experience in PCD saw blade sharpening, as he just starts this project recently.

I recommend him vitrified bond diamond wheel with 600# and 800#. And grinding wheel RPM is about 2000, amount of feed is 0.1mm for rough grinding, semi-fine grinding is 0.05-0.06mm, fine grinding is 0.03mm.

Feedback

After test, customer told me the working life is only 50% compare to ASAHI metal bond diamond wheel, and also have some noise during the grinding. However, he is satisfied with grinding wheel’s sharpness. Maybe the diamond wheel quality is not the single problem. I think the grinding parameter is not suitable. Cause customer is fresh in PCD saw blade grinding. He used to manufacture carbide saw and just start produce PCD saws. And now carbide saw is still his main products. He uses resin bond type wheel more, supplier is Suzhou Saili.

Solution

I told customer we have different type wheels, sharp wheel and long working life wheel. And we usually offer customer with sharp type wheel for the first time. We can adjust and offer long working life wheel to customer.

.jpg)

.jpg)

.jpg)

<< Prev Article:How to select the grinding wheel hardness of CNC cylindrical grinder

<< Next Article:Makino PCD cutter wire cutting machining solution-machining accuracy controlled to 0.5 μm

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220