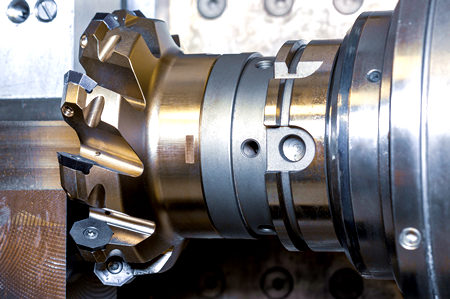

Indexable inserts is a kind of cutting tool which clamps a polygonal blade with several cutting edges in advance on the tool body by mechanical clamping method. When a cutting edge is blunt in the process of use, as long as the clamping of the blade is released after the rotation or replacement of the blade, so that the new cutting edge into the working position, and then after clamping can continue to use.

.jpg)

2. Indexable tools have two characteristics compared to welded and integral tools

(1) The insert mounted on the cutter body shall have at least two pre-machined cutting edges for use. (Some special blades cannot be transposed and can only be replaced, such as ball head blades)

(2) The position of the cutting edge after the transposition of the blade remains unchanged on the tool body and has the same geometric parameters.

3. Indexable inserts have the following characteristics compared with welding cutters

(1) The blade becomes an independent functional element, and its cutting performance is expanded and improved;

(2) The mechanical clamping type avoids the influence and limitation of welding process, and is more conducive to the selection of blades of various materials according to the processing object, and gives full play to its cutting performance, thus improving the cutting efficiency.

(3) The space position of the cutting edge is fixed relative to the tool body, which saves the auxiliary time needed for tool change and tool alignment and improves the utilization rate of the machine tool.

(4) Because of the indexable cutting tool high cutting efficiency, less auxiliary time, so improve the work efficiency, and the indexable tool body can be reused, saving steel and manufacturing costs, so its good economy. The development of indexable tool greatly promoted the progress of tool technology, while the professional and standardized production of indexable tool body promoted the development of tool manufacturing technology.

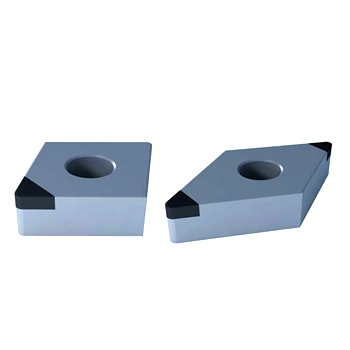

PCD indexable inserts: mainly used for mirror processing of aluminum alloy.

CBN indexable inserts: hardened materials with hardness above 55 ºHRC are more common in turning, but rarely in milling.

---Editor: Doris Hu

---POST:Doris Hu

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088