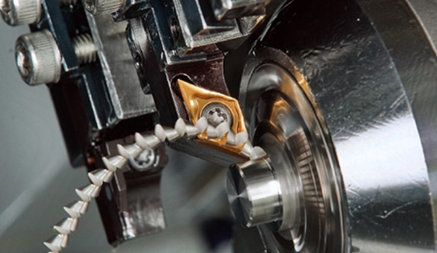

Chip control is one of the most important factors to consider in order to obtain high quality turning parts. Selecting the right cutting parameters and applying our application skills can achieve the desired part quality.

General rules for surface quality:

(1) Surface quality can often be improved by using higher cutting speeds.

(2) Insert grooves (center, positive and negative front angles, and positive back angles) affect surface quality.

(3) The choice of insert material has some effect on the surface quality.

(4) If there is a tendency to vibrate, a smaller tip radius is selected.

Successful chip control:

Chip control is one of the key factors in turning process and contains three basic chip breaking forms:

(1) Self-chipping (e.g. grey cast iron)

(2) Impact the tool to break chips

(3) Impact the workpiece to break chips

Influence factors of chip:

Insert groove: Whether the chip is more open or more compact depends on the width of the chip groove and the micro and macro structure design.

Tip radius: the control degree of small tip radius on chip is higher than that of large tip radius.

Main deflection Angle: Depending on the main deflection Angle, the chip is guided in different directions: toward or away from the shoulder.

Depth of cut: Depending on the material of the workpiece, a greater depth of cut will affect chip breaking, resulting in a greater cutting force to achieve chip breaking and removal.

Feed: Higher feed will usually produce higher chip strength. May aid in chip breaking and chip control in some cases.

Cutting speed: Changes in cutting speed may affect chip breaking performance.

Materials: Short chip materials such as cast iron are usually easy to work with. For materials with excellent mechanical strength and creep resistance, chip breaking performance is more concerned.

Cutting parameters of turning:

(1) When selecting the right speed and feed for turning, consider machine tools, cutters, inserts and materials.

(2) Start with a low feed rate to ensure blade safety and surface quality; Then the feed rate is increased to improve chip breaking performance

(3) Use a cut depth greater than the tip radius. This minimizes the radial deflection of the blade, which is important in inner circle machining

(4) Setting cutting speed too low will shorten tool life.

---EDITOR: Doris Hu

---POST: Doris Hu

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088