Makino PCD cutter wire cutting machining solution-machining accuracy controlled to 0.5 μm

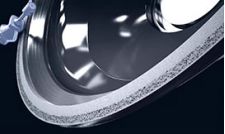

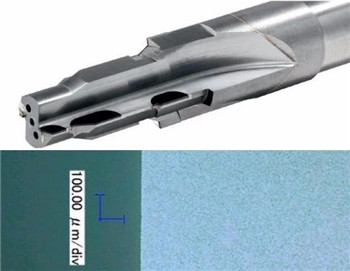

With the advent of new products, the application of new materials and ultra-precision surface machining are becoming more and more demanding also challenge to material cutting technology increasing. PCD tool has high machining accuracy, good wear resistance and long tool life. The requirements for cutting tools such as ultra-mirror milling and ultra-precision boring are also increasing and PCD tools are required to have better surface quality.

In addition to the excellent sharpening machine, the Makino Group also has a high-precision PCD tool processing machine, which is an oil-based wire cutting machine. This machine tool is developed for ultra-hard materials and ultra-high precision machining applications, cuts the mirror surface, and finally polishes it with almost no deterioration. This machine is a UPV series machine designed and manufactured by Makino Japan.

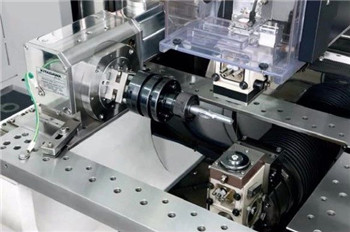

This machine tool has a highly rigid stacked design and is equipped with a high-precision power supply SPG-Ⅱ. The bed has good stability control. The interior can reach a constant temperature of ± 0.1 ℃, the minimum wire diameter is 0.05mm, and the best finish is Rz0.2μm. The accuracy is controlled to 0.5 μm.

On this basis that the PCD tool processing, through the selection of high-precision rotary axes, in conjunction with human-machine dialogue software and 3D simulation system, allows users to easily grasp its use.

For users, they only need to import the 3D model into the 3D simulation software configured by Makino to get the automatic measurement program of tool setting. The machine tool's configured Renishaw probe moves synchronously with the C axis to analyze and detect the shape and position of the PCD tool. The detected data will be directly transmitted to the man-machine interface of the machine tool to generate a machining program. After the 3D simulation inspection program has no problems, the program can be executed , Compensate the shape and position, the back angle required for cutting.

Processing case:

In addition, for larger tools with higher coaxiality requirements, the machine tool can also choose the tailstock support to ensure that the end of the tool is less than 2 μm in the process of machining.

When choosing a machine tool, the user needs to select a suitable size machine, UPV3 / UPV5, according to the diameter range and length range of the tool. You also need to pay attention to the clamping method of your handle, choose the appropriate adapter and probe diameter.

Under the complex and changeable processing conditions and processing requirements, Makino is professional and provides the best solutions. It is believed that it will bring more gains or help to users.

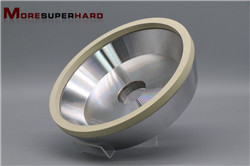

Similarly, MORESUPERHARD also can provide you with a vitrified diamond grinding wheel for PCD cutter tools that adapts to various processing conditions and processing requirements.

<< Prev Article:Vitrified bond diamond grinding wheel for PCD saw blade grinding

<< Next Article:Selection of cylindrical grinding wheel

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220

.jpg)

.jpg)