Case Studies

Case I

|

Workpiece |

Gear |

|

Cutting inserts |

PCBN – SNGN201020 |

|

Workpiece Materials |

40CrMo (45-55HRC) |

|

Cutting Parameters |

Roughing: Ap=4mm, f=0.7mm/r |

|

Finishing: Ap=0.5mm, f=0.6mm/r |

|

|

Cutting Method |

Gear Top cylindrical Turning |

|

|

|

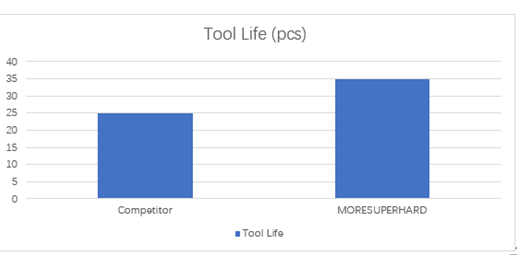

Comparison

|

Comparison |

Cutting Speed |

Efficiency |

Life |

|

Carbide inserts |

20m/min |

20h/pcs |

0.25pcs/edge |

|

MORESUPERHARD

CBN inserts |

50m/min |

2h/pcs |

2pcs/edge |

Case II

|

Workpiece |

Bearing |

|

Cutting inserts |

PCBN—SNGN150720 |

|

Workpiece Materials |

Gr15 (55-62HRC) |

|

Cutting Parameters |

Vc=120m/min |

|

Ap=4mm |

|

|

f=0.1mm/r |

|

|

Cutting Method |

Cylindrical / Face turning |

|

|

|

Case III

|

Workpiece |

Rotary Support Bearing |

|

Cutting inserts |

PCBN—RCGN090700 |

|

Workpiece Materials |

42CrMo (47-55HRC) |

|

Cutting Parameters |

Vc=90m/min |

|

Ap=0.2mm |

|

|

f=0.3mm/r |

|

|

Cutting Method |

Inner Circle Turning |

|

|

Comparison

|

Comparison |

Cutting Speed |

Efficiency |

Life |

|

Coated Alloy |

50m/min |

2h/pcs |

1pcs/edge |

|

MORESUPERHARD

CBN inserts |

90m/min |

30min/pcs |

4pcs/edge |

Case IV

|

Workpiece |

Crankshaft |

|

Cutting inserts |

PCBN—DNGA110408 |

|

Workpiece Materials |

42CrMo (42-47HRC) |

|

Cutting Parameters |

Vc=170m/min |

|

Ap=0.3mm |

|

|

f=0.1mm/r |

|

|

Cutting Method |

Excircle Interrupted Wet Turning |

|

|

Comparison

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088