PCD center point for machining high precison shaft

The advantages of PCD dead centers

? Ultra-high wear resistance, service life of 80-180 times that of hard alloy center.

? Good thermal conductivity, reduce the friction heat grnerated in the work and avoid the central hole of the workpiece being burned and deformed, causing changes in the central position and affecting the machining accuracy.

? The friction coefficient is much lower which cangreatly reduce the friction resistance. And the vibration of workpiece, to improve the processing accuracy.

? Polycrystalline diamond under 650° showed good chemical inertness, resistant to strong acid, alkali, suitable for all kinds of operating mode under the condition of work.

|

Type |

D2 |

D4 |

H1 |

L3 |

thread |

L1 |

L2 |

L2-l1 |

|

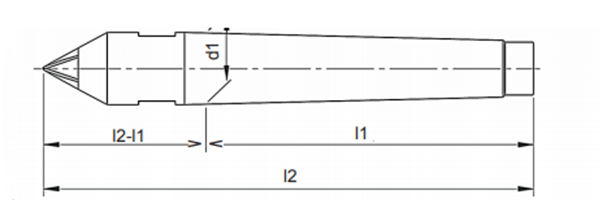

Full Center |

12.2 |

7 |

53.5 |

80 |

26.5 |

|||

|

18 |

7 |

64 |

100 |

36 |

||||

|

24.1 |

11 |

81 |

125 |

44 |

||||

|

34.6 |

14 |

102.5 |

160 |

57.5 |

||||

|

44.7 |

15.8 |

129.5 |

200 |

70.5 |

|

Type |

D2 |

D4 |

H1 |

L3 |

thread |

L1 |

L2 |

L2-l1 |

|

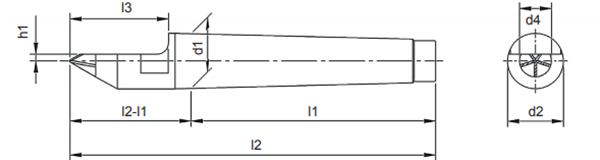

Half Center |

12.2 |

7 |

1.5 | 22 |

53.5 |

80 |

26.5 |

|

|

18 |

7 |

2 | 30 |

64 |

100 |

36 |

||

|

24.1 |

11 |

3 | 38 |

81 |

125 |

44 |

||

|

34.6 |

14 |

5 | 50 |

102.5 |

160 |

57.5 |

||

|

44.7 |

15.8 |

7 | 63 |

129.5 |

200 |

70.5 |

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088