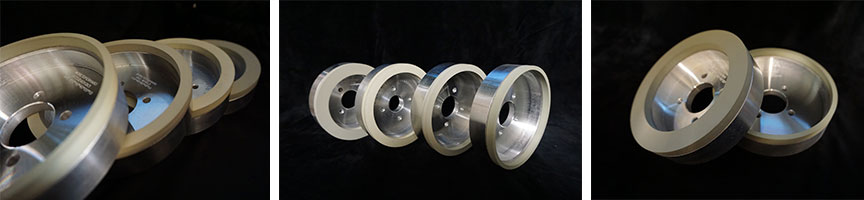

Introduction of vitrified bond diamond grinding wheel

Vitrified bond diamond grinding wheels possess pretty high abrasive resistance, especially in polishing hard and brittle workpiece. It has many advantages like high grinding efficiency, high grinding precision, excellent workpiece's surface grinding, etc

Application of vitrified diamond wheel

Especially for PCD tools rough, semi-fine and fine grinding.

Specification of 6a2 diamond wheel

|

TYPE |

Diameter D (mm)

|

Thickness T (mm)

|

Hole H (mm)

|

Diamond Width W (mm)

|

Diamond Thickness X (mm)

|

|

6A2 |

100 |

40 |

20,32,40 |

5, 10, 15, 20 |

10 |

|

6A2 |

125 |

40 |

32,40 |

5, 10, 15, 20 |

10 |

|

6A2 |

150 |

40 |

32,40 |

2, 3, 5, 10, 15 |

10 |

|

Grit Size: 80# -- 8000# (D213 – D1) |

|||||

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088