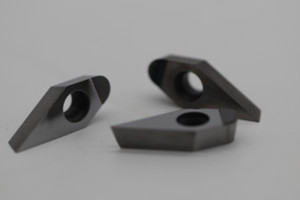

It is a composite superhard material sintered by diamond micropowder and binder cobalt under high temperature and ultra-high pressure (1400-1600°C, 5-7Gpa). It has high hardness, high wear resistance, high elastic modulus, Significant advantages such as isotropy and relatively high thermal conductivity

ABOUT PCD CUTTING TOOLS

PCD tool is a tool made by welding the PCD composite sheet to the carbide or steel cutter body. Because the PCD composite sheet combines the high hardness, wear resistance, low friction coefficient and strength of single crystal diamond with the hardness of tungsten carbide the high flexural strength of the alloy is combined, and the tungsten carbide layer of the composite sheet provides mechanical support for the diamond layer, increasing its flexural strength.

Misunderstanding of Material Processing In 3C Industry

The materials currently processed in the 3C industry are basically plastic + aluminum. And they all require the workpiece to have a good appearance after processing. Many practitioners from the mold industry generally believe that aluminum and plastic are very easy to process. This is a big misunderstanding.

Disadvantages of Carbide Tool Process 3C Products

For 3C products, as long as fiber-reinforced plastics are included, general carbide tools are used. If you want to obtain better appearance quality, the tool life is basically about 100 pieces. Especially in the current 3C industry, a large number of special-shaped contours are used, and it is far from easy for standard end mills to ensure the consistency of tools. Therefore, if the requirements for appearance parts are not reduced, the life of the carbide tool is up to 100 pieces, which is determined by the characteristics of the carbide tool itself.

Advantages of PCD Tool Process 3C Products

The PCD tool, because of its strong wear resistance and low friction coefficient, has a particularly good product consistency. As long as this PCD tool is done well, its lifespan must be over a thousand. Therefore, at this point, there is no way for carbide cutting tools to compete with PCD cutting tools.

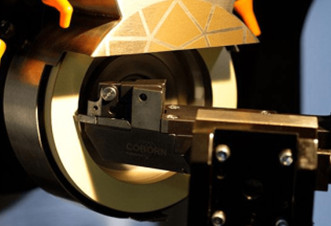

Traditional methods of processing PCD cutting tools

Powerful grinding Grinder: COBORN,EWAG,MYTECH

EDM Grinder:VOLLMER,FANUC

laser cutting Grinder:DMG,VOLLMER,AGATHON

One of the keys to PCD cutting tool manufacturing technology is to improve the sharpening quality of the cutting edge. If the high-quality tool head material lacks the ideal sharpening process and technology, it will cause a waste of resources. Use a good sharpening process and a more suitable grinding wheel. It will improve the product quality of the tool and reduce the cost of tool production and use.

Vitrified diamond grinding wheel for 3C products

The PCD blade edge grinding wheel should preferably be a ceramic diamond grinding wheel. The ceramic diamond has moderate strength, good self-excitation, and many internal pores, which is conducive to chip removal and heat dissipation. Sharpness is beneficial to improve the accuracy and efficiency of the machined surface, but attention should be paid to the selection of particle size. A coarser grinding wheel will lead to larger chipping of the cutting edge. The particle size is very closely related to the edge quality of PCD cutting tools.

PCD Ginding Solution From Moresuperhard

The ceramic diamond grinding wheel of Henan MoreSuperhard Materials Co., Ltd. has a very mature formula and process in the edge finishing of PCD cutting tools, which can help you solve the problem of rough and fine grinding of PCD cutting tools, and is equipped with dressing wheels to solve Follow-up wheel dressing issues. If you happen to have a PCD tool grinding problem, come to Henan Moao, we have the most complete solution.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088