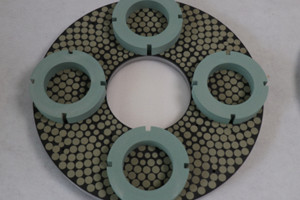

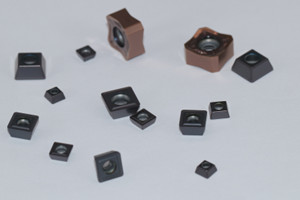

with the rapid development of industrial production, PCD cutting tools have gradually replaced traditional alloy blades with the advantages of high hardness, good stability and long life, becoming the "leader" in the current cutting tool industry.To this end, Moresuperhard has launched a double sided diamond grinding disc striving to help you produce more products that satisfy customers. Coupled with the increasing technical requirements, the requirements for PCD tool processing in various industries have changed from the initial stability and durability to higher precision, higher requirements and higher efficiency. To this end, Moresuperhard has launched a double sided diamond grinding disc striving to help you produce more products that satisfy customers.

Advantages of Inserts Top and Bottom double disk Grinding Wheels

1.The double sided dics has high efficiency, and can complete the processing of two parallel end faces of the blade at one time, reducing the traditional grinding process and eliminating the auxiliary time between processes.

2.The workpiece removal allowance is large and the workpiece allowance is gradually removed during the grinding process. The machining allowance that can be removed by other grinding machines and grinding methods can be removed at one time in several steps.

3.High machining accuracy: Double-end grinding is used to top and bottom workpieces through a rotary or linear feeder, and the machined double-end surfaces of the blade have high dimensional accuracy and geometric accuracy.

4.High degree of batch automation: double-face grinders are often used for stable production of large batches of workpieces, with stable processing quality and good workpiece consistency. High flatness and parallelism can be obtained.

Moresuperhard provide double sided diamond disc and derssing wheel.We can help you solve all the problem about carbide, ceramic, PCD and CBN inserts for diverse OEMs.Moresuperhard is committed to process research , development and innovation. Adhering to the concept of " more than grinding".

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088