What is wind turbine?

A wind turbine is a mechanical device that converts wind energy into electricity. Wind turbines are designed to convert the kinetic energy of the wind into mechanical energy, which is the movement of the shaft. Then, in a turbine generator, this mechanical energy is converted into electrical energy. The electricity generated can be stored in batteries or used directly.

The principle of wind power generation

The principle of wind power generation is to use the wind to drive the wind turbine blades to rotate, and then increase the speed of rotation through the speed increaser to promote the generator to generate electricity .

Wind Turbine Blade Trends

Wind turbine blades must be sufficiently light. Under the same wind speed, the lighter blades are easier to rotate, and the wind power conversion efficiency will be greatly improved. In addition, high strength and high toughness are required to meet service life requirements of several decades. Finally, the cost should be low. Therefore, the development of blade materials is a gradual lightweight, high-performance, and low-cost screening and development process.

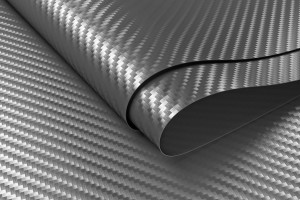

Wind turbine blades material:With the accumulation of application technology, long fiber reinforced polymer matrix composites have become the first choice for large wind turbine blade materials due to their excellent mechanical properties, process properties and environmental erosion resistance. The fibers here are mainly glass fiber and carbon fiber.

The difficults of machineing carbon fiber and glass fiber

Drilling is a common and important process in the processing of composite materials, especially carbon fiber. Hole machining on composite materials is prone to defects such as material burns, poor hole machining surface quality, delamination, tearing and collapse.

The pcd tool has a sharp and wear-resistant cutting edge,effectively solve the problems that arise during the processing of composite materials like material delamination, tearing, burrs and other defects.

Wind turbine blade’s length:13~60m

PCD inserts features:realizing high speed cutting, long service life.

PCD inserts specifications

WCGX06T308-A4-H

Moresuperhard company had been in ultra-hard abrasives more than 10 years,moresuperhard has complete PCD tools grinding solutions that has helped many pcd tools manufacturer solve problems.Moresuperhard provide quality pcd blanks for precision pcd cutting tools and quality vitrified diamond grinding wheel for grinding pcd tools that used in machining wind turbine blade.

More Super Hard Products Co. Ltd is a professional manufacturer of super hard tools, include PCD, PCBN, and Ceramic cutting tools. We are devoting to provide high-precision drilling, milling, reaming, threading and all tooling systems.

More Super Hard Products Co., Ltd. provide series cutting tools in different industry. Such like automobile, aerospace, electron, medical, energy, Hi-tech material.

More Super Hard” uses the most advanced EDM, Laser, vacuum brazing and grinding machines, also chooses the quality PCD, PCBN materials to make every tool perfect and reach a simple purpose of helping customer cost decreasing and benefit increasing.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088