Want to grind PCD and single crystal tools?

Moresuperhard can help you provide supporting solutions

Moresuperhard -vitrified diamond grinding wheels

Grain Sizes: 400# ~10000#

Application: PCD standard blades, turning tools, reamers, etc.

Features:

1. Anti-vibration pattern, improve the surface quality of the workpiece;

2. Good self-sharpening and high grinding efficiency;

3. Quality control, high workpiece precision;

4. Focus on the research and development of fine-grained grinding wheels, with good surface finish;

5. The grinding wheel has a long service life, less dressing times and easy dressing.

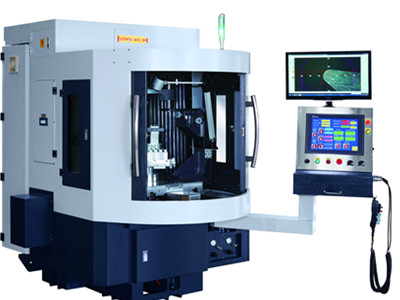

MYTECH --- PCD/CBN/MCD tools special grinding machine

Model: MT-198NC

Application: MT-198NC is a fully automatic grinding machine, specially suitable for PCD/CBN tool grinding, single crystal tool grinding.

Features:

1. German original CCD system and software to improve grinding accuracy;

2. The integral casting base reduces the chance of stress deformation;

3. Brushless servo motor, small size, light weight, high torque and high efficiency;

4. Powerful high-precision roller linear slide rails can meet different processing needs.

Ogura Gemstone Seiki---Vitrified Diamond Grinding Wheel

Grain Sizes: 400# ~ 10000#

Application: single crystal tool grinding

Features:

1. High precision of grinding workpiece;

2. Good stability, uniform abrasive layer and long service life;

3. High grinding efficiency and short processing time.

4. Reduce total cost.

<< :Why your diamond cutting tools can not reach ideal precision?

<< :The classfication of precision and ultra-precision machining

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088