Precision and ultra-precision machining classification

Traditional precision machining methods include abrasive belt grinding, precision cutting, honing, precision grinding and polishing.

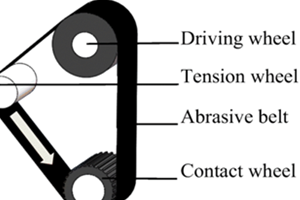

1.Abrasive grinding belt

Abrasive belt grinding is to process workpieces with abrasive blended cloth as abrasives. It belongs to the category of coated abrasives grinding.It has the characteristics of high productivity, good surface quality and wide application range.

2.Precision cutting

diamond tool cutting (SPDT), is used for cutting with high-precision machine tools and single crystal diamond tools. It is mainly used for precision machining of soft metals such as copper and aluminum that are not suitable for grinding, such as magnetic drums for computers , metal mirrors for magnetic disks and high-power lasers, etc., the accuracy of machining is 1~2 grades higher than that of general cutting.

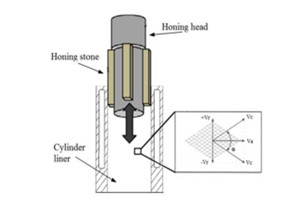

3.Honing:

a honing head composed of oil stone sand bars reciprocates along the surface of the workpiece under a certain pressure, and the surface roughness after processing can reach Ra0.4~0.1µ;m, preferably Ra0.025µ;m, mainly used for honing. To process cast iron and steel, it is not suitable for processing non-ferrous metals with low hardness and good toughness.

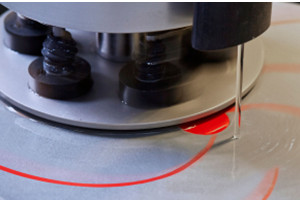

4.Precision grinding and polishing

Precision grinding and polishing is a machining method that makes the workpiece achieve the required size and precision through the abrasive and machining fluid between the workpiece and the tool, and the workpiece and the grinding tool are mechanically rubbed against each other. Precision grinding and polishing can achieve precision and surface roughness that cannot be achieved by other processing methods for both metal and non-metallic workpieces. The roughness of the ground surface is Ra≤0.025µ; m The processing metamorphic layer is small, the surface quality is high, and the precision grinding The equipment is simple, mainly used for the processing of plane, cylindrical surface, gear tooth surface and mating parts with sealing requirements, and can also be used for the finishing of gauges, gauge blocks, fuel injectors, valve bodies and valve cores.

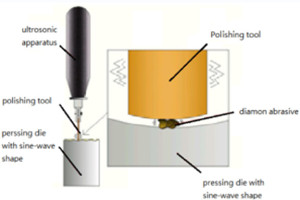

5.Polishing

Polishing is a kind of micro-processing on the surface of the workpiece by mechanical, chemical and electrochemical methods. It is mainly used to reduce the surface roughness of the workpiece. The commonly used methods are: manual or mechanical polishing, ultrasonic polishing, chemical polishing, electrochemical polishing and Electrochemical mechanical composite processing, etc. The surface roughness of the workpiece after manual or mechanical polishing is Ra≤0.05µ;m, which can be used for polishing of plane, cylinder, curved surface and mold cavity. The machining accuracy of ultrasonic polishing is 0.01~0.02µ;m, and the surface roughness is Ra0.1µ;m. The surface roughness of chemical polishing is generally Ra≤0.2µ;m. Electrochemical polishing can be increased to Ra0.1~0.08µm.

Precision machining includes processing technologies such as micromachining, ultra-fine machining, and finishing.

1.Micromachining technology refers to the processing technology for manufacturing tiny-sized parts.

2.Ultra-fine machining technology refers to the processing technology for manufacturing ultra-small size parts. They are proposed for the manufacturing requirements of integrated circuits. Due to the small size, the accuracy is expressed by the absolute value of the cut size, rather than the processed size. It is expressed as a ratio to the dimensional error.

3.Finishing generally refers to a processing method that reduces the surface roughness and improves the mechanical and mechanical properties of the surface layer, and does not focus on improving the processing accuracy. In fact, these machining methods can not only improve the surface quality, but also improve the machining accuracy. Finishing is a new term proposed in recent years. It corresponds to finishing, which means to reduce the surface roughness and improve the mechanical and mechanical properties of the surface layer, and to improve the machining accuracy (including size, shape, position accuracy).

ultra-precision machining

Ultra-precision machining is a process of micro-cutting materials on ultra-precision machine tools using the strictly constrained relative motion between the part and the tool to obtain extremely high shape accuracy and surface finish. The current ultra-precision machining refers to the processing technology in which the dimensional accuracy of the processed parts is higher than 0.1μm, the surface roughness Ra is less than 0.025μm, and the resolution and repeatability of the machine tool positioning accuracy are higher than 0.01μm. Micron-scale processing technology, and is developing to nano-scale processing technology.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088