What is alumina ceramic?

Alumina ceramics are an inorganic non-metallic material sintered at high temperatures. Due to its advantages of high temperature resistance, corrosion resistance, wear resistance and thermal shock resistance, its application scope has expanded rapidly in recent years. With the advancement of ceramic toughening and strengthening technology and the development of mechanical processing methods, the application prospects of alumina ceramics in various fields are becoming more and more broad.

Processing methods of alumina ceramics

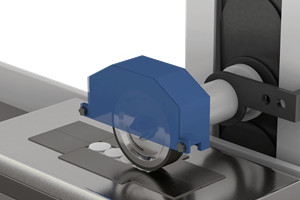

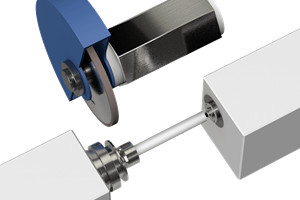

In the processing of alumina ceramics, common equipment include CNC machine tools and centerless grinders. CNC machine tools are mainly used to process products with complex shapes, such as engraving and milling machines and machining centers, while centerless grinders are suitable for processing products with regular shapes. Despite the variety of processing methods, due to the high hardness of alumina ceramics, the problems of high processing cost, low efficiency and poor precision have always plagued many manufacturing companies.

Main challenges in processing alumina ceramics

Alumina ceramics are mainly rough-processed by cutting in the unfired or calcined stage, and fine-processed by grinding after sintering. Due to the large processing allowance of ceramics, insufficient strength or surface processing defects are prone to occur in the unfired or calcined stage, resulting in the inability to obtain the ideal final processing shape. In addition, the uneven shrinkage during sintering also requires a large finishing allowance during rough machining, which further reduces productivity and increases costs. Another significant problem is the high cost of machining tools. Cutting requires the use of expensive sintered diamond and CBN tools, while finishing mainly relies on all-corona grinding wheels. Therefore, the tool cost for machining alumina ceramics is much higher than that of metal cutting tools, even dozens to hundreds of times higher. In addition, since alumina ceramics are very sensitive to processing conditions and difficult to achieve high-efficiency processing, their processing costs are much higher than ordinary materials.

Moresuperhard 's Solution for processing ceramic

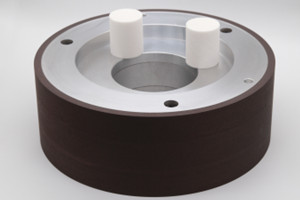

As a factory specializing in the production of diamond grinding wheels, Moresuperhard is committed to providing customers with efficient and economical alumina ceramic processing solutions. Our resin diamond grinding wheels have been unanimously recognized by our customers for their excellent cost-effectiveness, excellent surface treatment effect and efficient grinding ability. Whether it is external cylindrical grinding, internal cylindrical grinding or centerless grinding, our products can help you achieve high-quality alumina ceramic processing.

Choose Moresuperhard's diamond grinding wheel, you will enjoy:

High cost-effective processing tools

Excellent surface treatment effect

Efficient grinding ability

Contact us now to get a quote and let Moao help you achieve greater success in alumina ceramic processing!

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088