In modern manufacturing, tungsten steel (hard alloy) is widely used due to its high hardness and wear resistance. However, the requirements for tools when processing tungsten steel are extremely high, especially the selection of suitable grinding wheels is crucial in the grinding process. This article will share the case of us providing customers with high-quality grinding wheels and successfully solving their processing problems.

Grinding wheel specifications and customer feedback

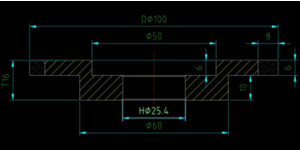

Customers use punch machines for dry grinding of tungsten steel, and processing efficiency and surface roughness are their main concerns. Moresuperhard engineers recommended a grinding wheel with specifications of

100-25.4-8-6 and a grain size of 600# resin diamond grinding wheel

The customer initially had doubts about the price, but after trial, the customer reported that our grinding wheel has superior performance, high processing efficiency, and good surface roughness, which is completely worth the price.

Problem analysis: sticky accumulation phenomenon

However, in actual use, the customer found that sticky deposits appeared on the right edge of the grinding wheel, affecting the processing effect. This phenomenon also existed in the grinding wheel used before, and the customer suspected that it was caused by the colloid of the resin in the grinding wheel. After analysis and observation, we found that the main reasons for sticky accumulation are as follows:

1. Tool stroke problem: The customer's tool stroke does not completely cover the outer circle of the grinding wheel, resulting in the edge part not being ground.

2. Dry grinding method: During dry grinding, due to lack of cooling, the friction between the grinding wheel and tungsten steel causes the material to melt and form sticky accumulation.

Solution for resin diamond grinding wheel sticky accumulation

In order to solve the problem of sticky accumulation, we proposed the following two solutions:

1. Increase tool stroke: Adjust the tool stroke so that it can completely cover the outer circle of the grinding wheel to ensure that the edge of the grinding wheel can also be ground.

2. Adjust the thickness of the grinding wheel: Reduce the thickness of the grinding wheel by 1-2mm so that it is not easy to produce sticky accumulation on the edge. In the end, the customer adopted our advice and successfully solved the problem of sticky accumulation by increasing the tool stroke.

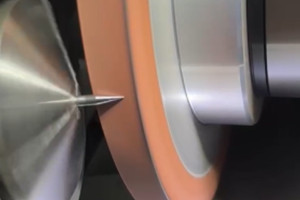

Grinding case for carbide punch

Through this case, we deeply realized the importance of selecting high-quality grinding wheels and the necessity of reasonably adjusting processing parameters. Although high-quality grinding wheels are more expensive, their superior performance and long life can significantly improve processing efficiency and product quality in actual use, and ultimately bring higher value to customers. At the same time, reasonable processing plans and careful adjustments can effectively solve various problems in the processing process and ensure the smooth progress of production. I hope that through the sharing of this article, it can provide a reference for more companies engaged in tungsten steel processing, select suitable grinding wheels and optimize processing parameters, and improve production efficiency and product quality.

<< :Processing methods of alumina ceramics

<< :Grinding Case-SG grinding wheel for 20CrMnTiH workpieces

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088