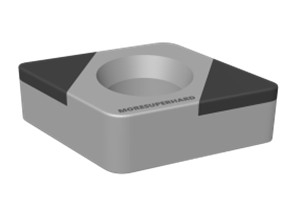

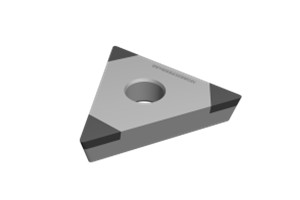

Introduction to indexable inserts

Indexable CNC inserts: Indexable inserts have multiple cutting edges. One cutting edge does not need to be re-sharpened after being blunted. It can continue to work after being indexed

Advantages of indexable inserts

High production efficiency: Since machine tool operators no longer need to sharpen tools, auxiliary time such as downtime for tool changes can be greatly reduced;

long service life: because the blade avoids defects caused by high temperatures in welding and sharpening, the cutting performance is stable and the tool life is extended;

Low tool costs: Indexable tools greatly reduce tool holder consumption and inventory, simplify tool management, and effectively reduce tool costs.

Moresuperhard resin diamond periphery grinding wheel

As the indexable tool market becomes increasingly popular, the usage of peripheral grinding wheels is also increasing day by day. Moresuperhard has studied and upgraded the original formula, and specially launched the cost-effective, stable and efficient resin peripheral grinding wheel M-C1101, which serves many small and medium-sized tool companies.

Resin peripheral grinding wheel M-C1101 is suitable for grinding indexable tools, flat tools, milling cutters, cutting tools, welding tools, CNC coating tools, and machine clamping tools made of cemented carbide, ceramics, CBN and other materials. Compared with other resin peripheral grinding wheels, the M-C1101 grinding wheel has better wear resistance and can bring higher processing efficiency.

At present, it has been successfully equipped with mid-to-high-end peripheral grinding and grinding machines such as Haibao, Tiantong, Weize, WAIDA, EWAG, AGATHON, and WENDT, and has received unanimous praise from customers.

✳Guarantees almost no clogging during the grinding process and no need for trimming;

✳The processing tool has stable dimensions and small chipping, which can meet various processing needs in the market;

✳Grinding efficiency and service life coexist, and the stability is good. It can cooperate with robotic arm production to ensure the stability of the workpiece;

✳ It can comprehensively improve grinding wheel performance, save manpower, improve processing efficiency, minimize production loss and downtime, and truly help customers reduce costs and increase efficiency.

Since its establishment, Moresuperhard has been exclusively providing customers with complete solutions as a system supplier. Develop correct and professional solutions for each of customers' needs, helping users to respond quickly to changing customer needs and consolidate their market position.

<< :How to Grind Precision Ceramic Materails?

<< :Classification And Application of Precision Ceramic Materials

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088