Introduction to Formnext + PM South China

The "2023 Shenzhen International Additive Manufacturing, Powder Metallurgy and Advanced Ceramics Exhibition" co-sponsored by Xinlian Elise and Guangya Messe Frankfurt will be held in Hall 6 of Shenzhen International Convention and Exhibition Center on August 29-31 . The exhibition covers the entire process chain of materials, design, software production equipment, pre- and post-processing, quality management, and measurement in the three major areas of powder metallurgy, advanced ceramics, and additive manufacturing. The scale of the exhibition is 20,000 square meters, and 300 Chinese and foreign companies are gathered to participate in the exhibition. During the same period, there will be as many as 80+ sessions of conference and forum guest speeches, and it is expected to attract 15,000 professional visitors.

Moresuperhard Looking forward to meet you at the exhibition site

Booth:E111

Moresuperhard also participated in this exhibition, you are welcome to come to our booth for in-depth communication. Now let's take a preview of our main exhibitors

Efficient diamond cutting wheel

(1) Used for cutting ceramics, ceramic composite materials, magnetic materials, circuit boards, fuse glass tubes, optical glass, quartz glass tubes, sapphire, hard alloy rods, high-speed steel, etc.

(2) High precision, high efficiency, good rigidity, sharp and durable, smooth cutting section without chipping, and long service life.

(3) Mainly exported to Europe, America and major domestic regions, the products are of high quality and cost-effective

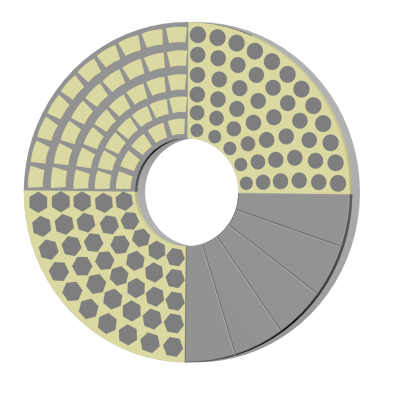

Diamond double end grinding disc

(1) The double-end grinding disc can process ceramics, cermets, alloys, tungsten steel, optical glass, sapphire glass, high-speed steel, bearing steel, tool steel, stainless steel, cast iron, etc.

(2) Vitrified diamond/CBN grinding discs can be used in single-sided or double-sided grinding systems.

(3) The grinding wheel has high grinding efficiency, high wear resistance and abrasive consumption, good surface quality and flatness of the workpiece, and the size can be customized.

Vitrified diamond internal grinding head

(1) Processing cemented carbide, ceramics, cermets, bearings, compressors, CVJ ball cages, hydraulic tappets, universal joints, stators, rotors, etc.

(2) High grinding precision, good surface quality and long service life.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088