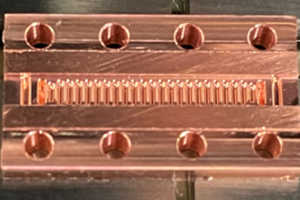

The characteristics of red copper

oxygen-free red copper has no hydrogen embrittlement, high electrical conductivity, good processability, weldability, corrosion resistance and low temperature performance. Copper has good heat transfer, elongation and corrosion resistance.

The scope of application of copper

Red copper materials are mainly used in electric vacuum instrument parts. Widely used in busbars, conductive strips, waveguides, coaxial cables, vacuum seals, vacuum tubes, parts of transistors, etc. It is also used in the processing of motor short circuit rings, electromagnetic heating sensors, high-power electronic components, terminal blocks, doors, windows, handrails and other furniture and decorations.

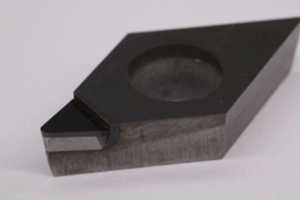

Why choose PCD tools to process copper?

Copper is widely used due to its good toughness and plasticity, but it is easy to stick to the cutting tools during processing.

PCD tools can process non-ferrous metal materials and their alloys such as: aluminum alloy, aluminum casting alloy, magnesium aluminum alloy, silicon aluminum alloy, copper alloy, red copper, brass, tungsten carbide hard alloy, ceramics and other materials.

PCD inserts can be used for high-speed cutting, which can effectively improve production efficiency and save production costs. PCD tool processing copper materials can obtain better surface finish and improve surface processing quality.

How to grind PCD tools for processing copper?

when the copper material is relatively sticky to the cutting tools, the most important thing in processing is that the rake angle must be large when grinding the turning tool, and the chip flute must be opened greater than 5mm, and the depth is best Between 2mm and 3mm, it is not easy to generate heat when turning copper materials, and the turning process is smoother and the surface finish is better.

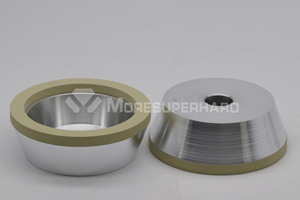

Moresuperhard provide vitrified diamond grinding wheel for grinding PCD tools including pcd turining tools,pcd milling tools and pcd reamers.Moresuperhard provide 11A2,1A1,3A1,14A1 and other specifications diamond grinding wheel for pcd tools chipping breaker processing.

Diamond wafers have great potential in high-end fields such as quantum computing, microwave power devices, and semiconductor lasers due to their ultra-high hardness, excellent thermal conductivity, and wide bandgap properties.

Discover how our ceramic diamond grinding wheels enhance efficiency and precision in PCD chrome-plated workpiece machining. With optimized grinding processes, extended tool life, and improved surface finish, our solutions help manufacturers achieve higher productivity and lower costs.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088