1. Highlight chamfering tool

|

Tool specifications |

Φ1~Φ4 |

|

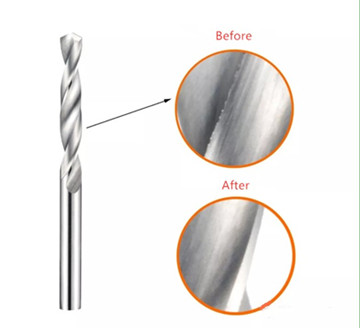

Specification of passivation sand before coating |

600 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds

|

|

Specification of passivation sand after coating |

600 |

|

Passivation time after coating |

Frequency: 40

All reverse passivation, set the time according to the passivation value.

Ensure that the cutting edge passivation value is 3~4um.

|

|

Tool specifications |

Φ6~Φ25 |

|

Specification of passivation sand before coating |

400 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds

|

|

Specification of passivation sand after coating |

400 |

|

Passivation time after coating |

Frequency: 40

All reverse passivation, set the time according to the passivation value.

Ensure that the cutting edge passivation value is 3~4um.

|

2.

|

Tool specifications |

Φ1~Φ4 |

|

Specification of passivation sand before coating |

600 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds

|

|

Specification of passivation sand after coating |

600 |

|

Passivation time after coating |

Frequency: 40

1 to 1 ratio of positive and negative passivation.

Ensure the blade passivation value of 6~7um.

|

|

Tool specifications |

Φ6~Φ25 |

|

Specification of passivation sand before coating |

400 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds |

|

Specification of passivation sand after coating |

400 |

|

Passivation time after coating |

Frequency: 40

1 to 1 ratio of positive and negative passivation.

Ensure the blade passivation value of 6~7um. |

3. Milling cutters (forming cutters, arc cutters)

|

Tool specifications |

Φ1~Φ25 |

|

Specification of passivation sand before coating |

600 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds |

|

Specification of passivation sand after coating |

600 |

|

Passivation time after coating |

Frequency: 30

seconds Reverse rotation: 30 seconds |

Precautions

1. Replacement of passivated sand. When the passivation time of 400# sand tool is more than 20 minutes, the sand needs to be replaced or redeployed.

2. After the replacement of new sand, the passivation time of the first mode tool should be reduced. The passivation time cannot be reached once, but should be gradually extended to the range.

3, for the small number of sample knives, clamping should be separated from the isolation of clamping passivation.

4. The passivation time of the first mode tool at work should be reduced by 3 minutes every day. The passivation time should not be put into place once, and the passivation time should be gradually extended to the range.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088