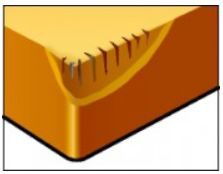

Ⅰ、Flank wear

Formation reason: mechanical friction between workpiece and back tool surface, cutting speed is too high, material wear resistance is insufficient, feed rate is too low, wear is formed in the back. Treatment measures:

1. Use a more durable blade material

2. Increase the feed

3. Reduce cutting speed

4. Increase coolant pressure

5. Check and correct tool center height

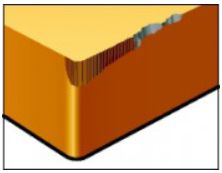

Ⅱ、Crescent depression wear

Formation reason: the blade material diffusion and the friction between the front tool surface and the workpiece cause internal front tool surface wear.

Treatment measures:

1. Reduce cutting speed

2. Use blade grooves with larger front angles

3. Use a more abrasive blade material

4. Reduce feed

5. Increase coolant pressure

6. Check and correct tool center height

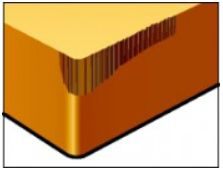

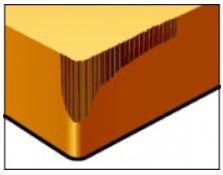

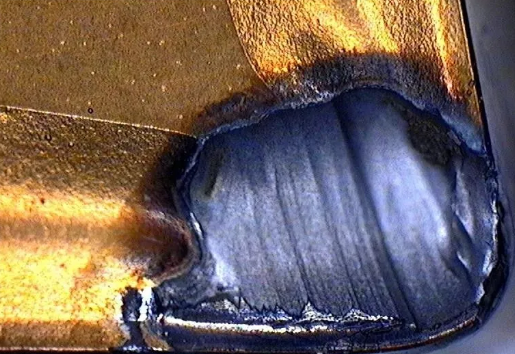

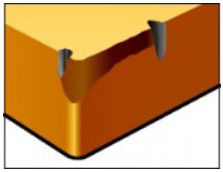

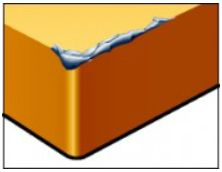

Ⅲ、groove wear

Formation reason: Grooves wear often occur when hard - skinned workpiece is processed (forging or casting).

Treatment measures:

1. Cutting at different cutting depths

2. Reduce cutting speed

3. Use a blade material with better toughness

4. Use the main cutting edge of the blade to cut (a tool with a smaller main Angle)

5. Check and correct tool center height

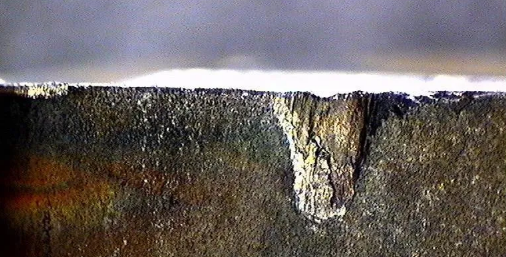

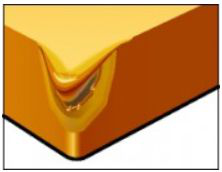

Ⅳ、Plastic deformation

Formation reason: Excessive thermal load and excessive cutting resistance lead to cutting edge deformation.

Treatment measures:

1. Choose more wear-resistant blade material

2. Reduce cutting speed

3. Reduce the feed

4. Reduce cutting depth

5. Increase coolant pressure

6. Check and correct tool center height

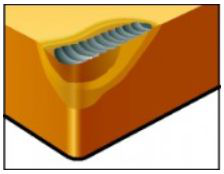

V、hot crack

Formation reason: intermittent machining or variable cutting fluid supply

Treatment measures:

1. Choose materials with higher toughness and better thermal impact resistance

2. Cutting fluid should be used in sufficient amount or not at all

Ⅵ、Flaking

.png)

Formation reason: vibration, discontinuous cutting, chip impact, or blade material is too hard, resulting in breakage along the direction of the cutting edge.

Treatment measures:

1. Reduce cutting speed

2. Reduce the feed

3. Use a blade material with better toughness

4. Use more stable cutting edges

5. Check the stability of the tool during vibration

6. Stop supplying coolant when discontinuous cutting

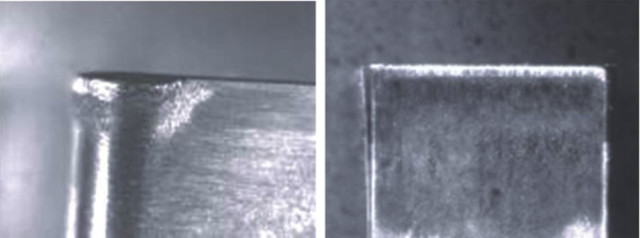

Ⅶ、Built-up edge

.png)

.png)

Formation reason: the cutting area temperature is too low, or the material viscosity is very high, such as mild steel, stainless steel and aluminum

Treatment measures:

1. Improve cutting speed VC

2. Use coolant wisely (e.g., increase concentration)

3. Switch to a more suitable blade groove (blade with reduced force geometry and/or smooth surface)

----EDITOR: Lexi Pang

----POST: Jackie Wang

<< :Advantages of processing aluminum with PCD tool

<< :PCD tool cutting edge collapse how to control within 5μm

A technical guide to selecting diamond grinding wheels for PDC cutter . Learn how ceramic and resin bond diamond wheels improve efficiency, precision, and tool life in oil & gas and mining applications.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088