News

Home / News / Industry News > Tools History

A short passage about the history of Tools

The development of cutting tools occupies an important position in the history of human progress.

China as early as in the BC 28 ~ 20 centuries ago, there have been brass cones and copper cones, drills, knives and other copper knives.In the late warring states period (3rd century BC), as a result of mastering the carburizing technology, made copper knives.The drills and saws of that time had some resemblance to the modern flat drill and saw.

1.Tools History

The rapid development of cutting tools came in the late 18th century with the development of steam engines and other machines.

In 1783, the first milling cutter was made in Rene, France.In 1923, schleter of Germany invented cemented carbide.When using cemented carbide, the efficiency is more than twice as high as that of high speed steel.

Due to the high price of high speed steel and cemented carbide, in 1938, the German company DE guesa obtained the ceramic tool patents.In 1972, general electric produced polycrystalline synthetic diamond and polycrystalline cubic boron nitride blades.These nonmetallic tool materials enable the tool to cut at a higher speed.

In 1969, Sweden sandvik steel mill obtained the patent for producing titanium carbide coated carbide blades by chemical vapor deposition method.In 1972, physical vapor deposition was developed at bonsha and laguran in the United States to coat carbide or high-speed steel tool surfaces with titanium carbide or titanium nitride hard layers.The surface coating method combines the high strength and toughness of the matrix material with the high hardness and wear resistance of the surface material, so that the composite material has better cutting performance.

Due to the high temperature, high pressure, high speed, and working in corrosive fluid media parts, its application of more and more difficult to process materials, the level of automation and machining accuracy of the requirements for higher and higher.In the choice of tool Angle, need to consider the influence of a variety of factors, such as workpiece materials, tool materials, processing properties (coarse, finishing), must be reasonable according to the specific situation.

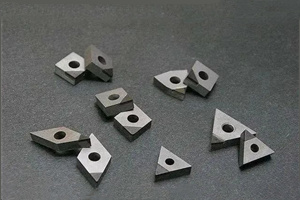

Common cutting tool materials: high speed steel, cemented carbide (including cermet), ceramics, CBN (cubic boron nitride), PCD (polycrystalline diamond), As they become harder and harder, the cutting speed increases., therefore, the hardness and cutting speed of PCD are the highest among them

High speed steel: can be divided into ordinary high speed steel and high performance high speed steel.

Ordinary high speed steels such as W18Cr4V are widely used in the manufacture of a variety of complex cutting tools.Its cutting speed is generally not too high, when cutting ordinary steel material is 40-60m/min.

High performance high speed steel, such as W12Cr4V4Mo, is made by adding some carbon content, vanadium content and cobalt, aluminum and other elements in ordinary high speed steel.Its durability is 1.5-3 times that of ordinary high speed steel.

According to gb2075-87 (according to the 190 standard) can be divided into three categories of P, M, K, P type of cemented carbide is mainly used for processing long chips of black metal, marked with blue;Class M is mainly used for processing ferrous metals and non-ferrous metals, with yellow as the mark, also known as general carbide, class K is mainly used for processing short chips of ferrous metals, non-ferrous metals and non-metallic materials, with red as the mark.

The Arabic numerals after P, M and K represent its performance and the conditions or processing conditions under which it bears the load during processing. The smaller the number, the higher the hardness and the worse the toughness.

4.Ceramics

Ceramic material wear resistance is good, can process the traditional tool is difficult to process or can not process the high hard material.In addition, ceramic cutting tools can avoid the power consumed by annealing processing, and therefore can improve the hardness of the workpiece, extend the service life of the machine.

Ceramic cutting blade and metal friction is small, cutting is not easy to adhere to the blade, not easy to produce debris, plus high-speed cutting.So in the same condition, the workpiece surface roughness is relatively low.Tool durability is several times or even dozens of times higher than traditional tools, reducing the number of tool changes in processing.

High temperature resistance, red hard good.Continuous cutting at 1200℃, so the cutting speed of ceramic blades can be much higher than that of hard alloy.Can carry on the high speed cutting or realizes "with the car, the milling replaces the grinding", the cutting efficiency is higher than the traditional cutter 3-10 times, achieves saves the man-hour, the electric power, the machine tool number 30-70% or higher result.

5.CBN

This is the second high hardness material known, CBN compound tablet hardness is commonly HV3000 ~ 5000, has the very high thermal stability and high temperature hardness, and has a high antioxidant capacity, also does not produce oxidation phenomenon in 1000 ℃, during 1200 ~ 1300 ℃ also does not react with iron materials, has good thermal conductivity and low friction coefficient.

6.Polycrystalline diamond PCD

Diamond tool has the characteristics of high hardness, high compressive strength, good thermal conductivity and good wear resistance, etc., which can obtain high machining accuracy and machining efficiency in high speed cutting.Because the structure of PCD is a sintered body of fine grain diamond with different orientations, its hardness and wear resistance are still lower than that of single crystal diamond, although the mixture is added.The affinity with nonferrous metal and nonmetallic materials is very small, in the process of processing chip is not easy to bond on the tip of the tool to form a chip tumor.

The respective application range of materials:

High speed steel: mainly used in the molding tool and shape complex and some other need high toughness occasions;

Carbide: wide application range;

Ceramics: mainly used in hard parts turning and cast iron parts rough machining and high-speed machining;

CBN: mainly used in hard parts turning and cast iron parts high-speed processing (generally speaking, than ceramic wear resistance, impact toughness and fracture resistance performance of high efficiency);

PCD: mainly used in non - ferrous metal and non - metallic materials for efficient cutting.

<< Prev Article:Grinding Fluid Selection In PCD Tools Grinding

<< Next Article:Precision grinding of super-hard abrasive wheels

Vitrified bond diamond grinding wheels possess pretty high a...

Our company mainly develops a new making holes’ method for P...

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220