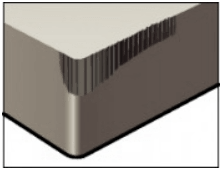

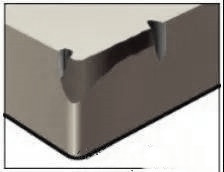

Flank wear

1.Rapid wear results in poor or out-of-tolerance surface quality

Reason:

Excessive cutting speed

Insufficient wear resistance

Feeding too low

Solution:

Reduce cutting speed (VC)

Choose materials with higher wear resistance

Raise the feed (fz)

2. Excessive wear leads to short tool life

.png)

Reason:

Vibration

Chip recutting

Burrs form on parts

Surface poor quality

generate heat

Solution:

Raise feed (FZ)

Adopt suitable milling

Use compressed air for effective chip removal

Check the recommended cutting parameters

Reason:

Tool run out

Vibration

Short tool life

Surface poor quality

loud noise

Solution:

Reduce the runout amount to less than 0.02mm

Check collet and collet

Minimize tool overhang

Use fewer teeth for cutting

Choose a larger tool diameter

For solid carbide end mills and replaceable head mills, select groove types with larger helical Angle (GP ≥45°)

Divide axial depth (AP) into multiple cutting knives

Reduced feed (FZ)

Improve tool and workpiece clamping

Crater wear

Excessive wear results in reduced cutting edge strength. A broken cutting edge results in poor surface quality

Reason:

The cutting temperature of the front blade surface is too high, which leads to diffusion wear

Solution:

Choose the alumina coating material

Choose the groove shape of front Angle blade

Lower the speed to get a lower temperature, and then lower the feed

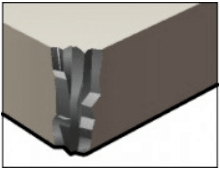

Tipping

The part of the cutting edge that is not involved in the cutting is damaged by a chip hammer. The front and support surfaces of the blade are damaged, resulting in poor surface texture and excessive wear of the rear blade surface

Reason:

The chip is compressed under the action of the cutting edge

Solution:

Choose a brand with higher toughness

Choose a blade with a stronger cutting edge

Improve cutting speed VC

Select the front Angle groove

Reduce feed at the beginning of cutting

Improve Dimensional Stability

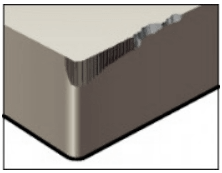

Groove wear

Trench wear results in poor surface quality and cutting edge fracture risk

Reason:

Work hardening material

Epidermis and oxide skin

Solution:

Reduced cutting speed (VC)

Choose a brand with higher toughness

Use a stronger groove

Use a cutting Angle closer to 45°

Use a round blade to ensure best results

Delay wear using variable AP technology

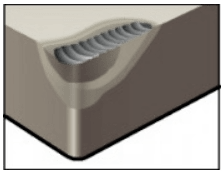

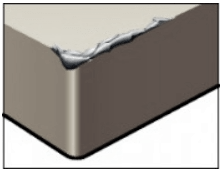

Built-up edge

The filamentous tumor results in poor surface quality and breaks the cutting edge when detached

Reason:

The cutting area is too cold

Materials such as mild carbon steel, stainless steel, and aluminum are highly viscous

Solution:

Increase cutting speed

Switch to a more suitable blade groove

Diamond wafers have great potential in high-end fields such as quantum computing, microwave power devices, and semiconductor lasers due to their ultra-high hardness, excellent thermal conductivity, and wide bandgap properties.

Discover how our ceramic diamond grinding wheels enhance efficiency and precision in PCD chrome-plated workpiece machining. With optimized grinding processes, extended tool life, and improved surface finish, our solutions help manufacturers achieve higher productivity and lower costs.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088