Surface Grinding wheel for tungsten carbide mold

Introduce of tungsten carbide mold

Tungsten carbide is a kind of material with high strength and excellent abrasion resistance. It is basic composition is wc-co (tungsten carbide), the important factor of super hard alloy structure depends on C (carbon) content.

.png)

1.Rough and fine grinding

Size of rough processing hexahedron:

There is an extra 0.05mm allowance for finishing on the basic size of the drawing.

The work piece parallel and perpendicular: ∥、⊥≤0.005mm

The dimension tolerance of the finished hexahedron is: +0.001/0~+/-0.002mm

parallel and perpendicular: //、⊥≤0.002mm

Surface roughness Ra≤0.15 microns

2.How to choose the grinding wheel

|

Using Resin bond diamond grinding wheel can divide into rough and fine grinding |

||

|

|

Rough grinding |

Finish grinding |

|

Cooling |

wet |

wet |

|

grit |

150-230# |

400-800# |

|

Concentration |

75% |

75% |

|

Binding degree |

medium or high. |

medium |

The relationship between bond and sharpness and life:

The sharper the grinding wheel is, the higher the machining efficiency will be. If need the sharpness and grinding efficiency should choose grinding wheel with lower "union degree". If need longer service life can choose grinding wheel with higher "binding degree"

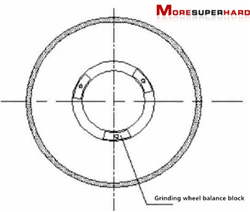

3. Static and dynamic balance of grinding wheel:

In order to eliminate the beating, ensure the stable rotation of the grinding wheel uniform loss, make the work piece surface roughness uniform, avoid left a jump mark on the surface after processing.

Picture 1. Grinding wheel with flange installed

.png)

Picture 2. Grinding wheel static balance

<< Prev Article:How to achieve mirror grinding with grinding wheel

<< Next Article:Brief Discussion on Grinding Process of CBN Tools

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220