Brief Discussion on Grinding Process of CBN Tools

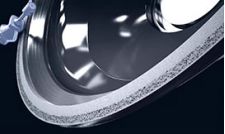

Cubic boron nitride CBN (Cubic Boron Nitride) is the first in 1950s by the U.S. General Electric Company (GE) using artificial synthetic method in high temperature and high pressure, and its hardness only to diamond is much higher than that of other materials, so it is with diamond all called super hard materials.

Cubic Boron Nitride, a sintered CBN used in cutting tools, was developed by the former Soviet union, China, the United States, Britain and other countries in the 1970s. Since then, CBN (cubic boron nitride) with its superior cutting performance is applied to the cutting of high hardness materials and difficult to machining materials, such as quench steel, high alloy wear-resistant cast iron, high temperature alloy, high speed steel, surface spray welding materials, sintered metal materials and other difficult to machining materials.

.png)

For the process that allowance is smaller than 0,5mm, we can choose pcbn inserts and brazed pcbn insert. For the process that allowance is larger than 0.5mm, we can choose solid cbn inserts.

PCBN compact inserts: used for high speed cutting, good wear and damage resistance, high strength, suitable for semi-finishing and finishing machining.

Brazed PCBN inserts: high speed cutting, more cutting edges,having straight hole and counter bore, can be easily installed onto standard tool holder. Excellent wear resistance, suitable for semi-finishing and finishing machining.

Solid CBN inserts:The solid CBN tools are made of CBN material, and there is no hole in the middle. It needs professional arbor to match, both sides of the cutting edges can be used for cutting, excellent impact and wear resistance ,mainly used for roughing process.

Application of CBN tools.

(1) High-speed cutting: mainly reflected in the field of ordinary gray cast iron.The maximum line speed of gray cast iron initially processed with traditional carbide inserts should not exceed 350 m/min, and vice versa. However, the maximum linear speed of gray cast iron processed by CBN tools can reach 1500m/min (on the basis of machine rigidity), and high wear resistance and high surface quality of the workpiece to be machined are ensured.

(2) Heavy-duty cutting: mainly in the field of high-hardness cast iron/cast steel, such as roll and pump materials used in large-scale equipment, large blank machining allowance, and need for cutting tools with excellent wear resistance and impact toughness, and the CBN tools can reach a depth of 10mm at a time, greatly improving production efficiency.

(3) Dry cutting: The CBN tools have high temperature and red hardness and can withstand normal cutting at a high temperature of 1200 °C. Guarantee excellent durability. Moreover, it reduces the unnecessary cost of machining the workpiece with the cutting fluid and ensures a good production environment.

TAG: Application of CBN tools

<< Prev Article:Surface Grinding wheel for tungsten carbide mold

<< Next Article:Vitrified bond diamond grinding wheel for PCD saw blade grinding

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220