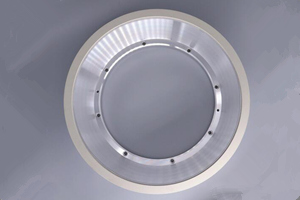

The wheel size: D350*T75*H240*W15*X10 SDC 3000# for PCD inserts.

Cutting speed: 12—20 M/S

Pre grinding Low Grit:600#

Universal grinding Medium Grit: 1200#

Finish grinding High Grit: 2500#

Fine grinding Super High Grit: 3000#

PCD or CBN cutting tools have the highest quality requirements. Precise geometries and minimal chipping are the essential quality requirements.

These grinding wheels deliver the required cutting ability with high stock removal performance and high dressing intervals. The grinding wheel is also very easy to dress.

This Peripheral diamond grinding wheel used for Waida APX-101, it is one of fully Automatic Insert Periphery Grinder, the global basic machine with selectable options that supports wide variety of needs and Made in Japan.

<< :How to prevent vibration of grinding wheel machine

<< :Agathon grinding machine application –typical cutting tools grinding

Discover how our ceramic diamond grinding wheels enhance efficiency and precision in PCD chrome-plated workpiece machining. With optimized grinding processes, extended tool life, and improved surface finish, our solutions help manufacturers achieve higher productivity and lower costs.

Moresuperhard provides high-precision copper wheel electrodes for EDM machining of PCD tools, including shaping, slotting, and edge finishing. Using Moresuperhard's copper wheel electrodes enhances machining accuracy, reduces chipping, extends tool life, and improves production efficiency.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088