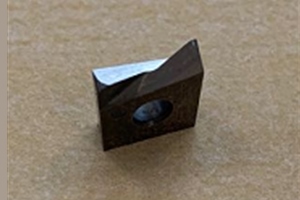

Cutting tools: TORO

Material: carbide

Machine: AGATHON Evo Penta

Software options: FRP free reference plane, Edge grinding wheel corner grinding

Special device: horizontal turning table

Cooling method: grinding oil cooling

Online cleaning: none

Machining allowance: 0.2mm

Processing time per side: 100 s (including loading and unloading and measuring time)

Drive head: lengthened/center hole positioning

Clamping head: standard

Feeding Prism: Standard

Automation

Loading and unloading: manipulator

Material tray: vertical tray or horizontal tray (horizontal tray requires electromagnetic suction head and turntable head)

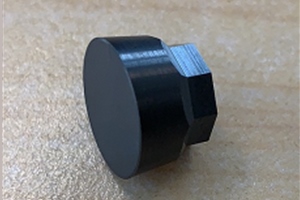

Material: ceramic

Machine: AGATHON Dom Plus

Software options: none

Special device: none

Grinding wheel: grit size 28, Φ350, wheel layer width 10mm, wheel layer thickness 10mm

Cooling method: grinding oil cooling

Dressing wheel: grit 240#

Online cleaning: none

Machining allowance: 0.7mm circumference

Processing time: 155 s (Including loading and unloading and measuring time)

Frock clamp

Drive head: standard Φ10mm

Clamping head: standard Φ8mm

Feeding Prism: Standard 800

Automation

Loading and unloading: manipulator

Material tray: vertical tray

Moresuperhard single-crystal diamond heat sinks offer ultra-high thermal conductivity (>2000 W/m·K), excellent electrical insulation, and a lightweight design, making them ideal for 5G, high-performance computing, RF power devices, semiconductor lasers, and aerospace applications.

Discover the key to optimizing single-crystal diamond tool performance with the right crystal face selection. Learn about (100) and (110) faces, their applications in precision machining, metal cutting, and semiconductor processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088