1. The principle of high frequency welding

High frequency induction heating technology is a heating technology developed at the beginning of the 20th century. It has fast heating speed, internal heating of materials and thermal efficiency. It has a series of advantages such as uniform and selective heating, good product quality, almost no environmental pollution, and easy realization of production automation. It has been widely used in the field of superhard tool manufacturing.

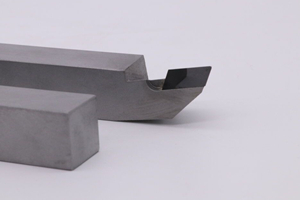

High-frequency induction brazing refers to a welding method that uses the principle of electromagnetic induction to convert electromagnetic energy into heat energy in the solder and workpiece, and heat the solder to a molten state, thereby welding the workpieces together. This process has fast heating speed, power density up to 10-100kW/cm2, and usually can complete the heating process within a few seconds, and can ensure the dimensional accuracy of the parts, and its shear strength can reach 300-400MPa.

2. Selection of brazing filler and flux for high frequency welding

The choice of flux and solder is one of the main factors that determine the brazing strength of PCD tools. Their reasonable combination can ensure that the molten solder has good fluidity, fully wets the base material, and reduces defects such as pores and slag inclusion. Brazing joints with beautiful appearance and excellent performance. Silver-based solder is considered to be an ideal solder at present. The shear strength of brazed cemented carbide joints is generally around 200MPa, and the shear strength can reach 300~400MPa when high-frequency induction brazing heating is used.

3. High frequency welding temperature and time

Affected by the cobalt-based binder inside the PCD, the tool material will be thermally damaged when the temperature reaches 700℃ or higher, which will affect the cutting performance, so its welding cannot use the high-temperature brazing process as high as 1000℃ like cemented carbide. On the other hand, if the soldering temperature is too low, it will affect the wettability of the solder, making it prone to desoldering during subsequent processing and use. Take PCD blanks from Element Six Company as an example, it is recommended that the brazing safety temperature of CTBO02 should be lower than 650℃, the welding temperature of CTB010 should be lower than 670℃, and the welding temperature of CTB025 should be lower than 720℃. In addition, when brazing PCD blanks, K-type cemented carbide with higher cobalt content should be the first choice, which is beneficial to improve the brazing strength.

The welding time refers to the time to maintain the welding temperature. If the holding time is not enough, it will be difficult for the flux to melt fully and uniformly, which will also cause the phenomenon of weak welding. If the holding time is too long, the PCD cutting edge will affect its cutting performance due to prolonged exposure to high temperature. When the PCD blanks t is brazed by high-frequency induction, the best temperature holding time is 15-20s.

4. High-frequency welding slow cooling measures

When steel is used as the base material, slow cooling measures should be taken after welding, which can help reduce or eliminate the welding stress caused by the inconsistent thermal expansion coefficient of the tool material and the base, and effectively prevent the occurrence of cracks. Common measures include artificial air cooling, asbestos boards at intervals, burying of thermal insulation powder such as quicklime or alumina, and placing in a holding furnace. After the tool is welded, it should be avoided to cool it naturally in the air, and it should not be quickly cooled in water or oil.

5. High frequency welding post-welding treatment

Excess flux and surface oxide scale should be cleaned in time after welding. The flux can be removed by soaking in hot water, but the best way to remove the oxide scale is sandblasting. Sandblasting can be carried out directly after welding and cooling. After cleaning, use a magnifying glass to inspect the brazing seams. Smooth, no porosity, no cracks, and arc-shaped brazing seams are ideal. Production experience shows that fine-grain shot peening has a good effect on passivating surface defects.

Moresuperhard single-crystal diamond heat sinks offer ultra-high thermal conductivity (>2000 W/m·K), excellent electrical insulation, and a lightweight design, making them ideal for 5G, high-performance computing, RF power devices, semiconductor lasers, and aerospace applications.

Discover the key to optimizing single-crystal diamond tool performance with the right crystal face selection. Learn about (100) and (110) faces, their applications in precision machining, metal cutting, and semiconductor processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088